With quality tools and correct materials, cleaning your rifle barrel is relatively easy.

Two types of fouling build up in rifling. The least detrimental to accuracy and the easiest to clean out is carbon fouling. It’s the soot-type residue left by the burning gunpowder. The other type is copper fouling. It’s copper residue that’s basically smeared off the bullet into the pores and microfractures of the steel barrel.

You are viewing: Which Direction Do You Clean A Gun Barrel

Typically, the faster the velocity of your cartridge/bullet combination, the faster fouling builds up (both carbon and copper) and the heavier it builds.

At some point, accuracy begins to degrade, and to regain top performance you’ve got to clean all that fouling out. Just how many rounds you can fire before degradation occurs depends on the quality of your rifle’s bore. Very smooth bores with minimal machining and tool marks usually can be shot far more times before accuracy begins to drop off.

Once you notice a reduction in precision, or maybe before you begin working up and tuning a new handload, or even just because you like knowing your rifle’s barrel is in good health, occasionally you need to give your barrel a good deep cleaning.

Here’s how to clean most effectively, using tools and solvents that are safe for your bore and enhance accuracy.

Tools, Solvents and Oils

For starters, always clean from the breech. Unless you can’t, that is; for example when cleaning a pump-action or semiautomatic or lever-action design that doesn’t allow access to the back of the barrel.

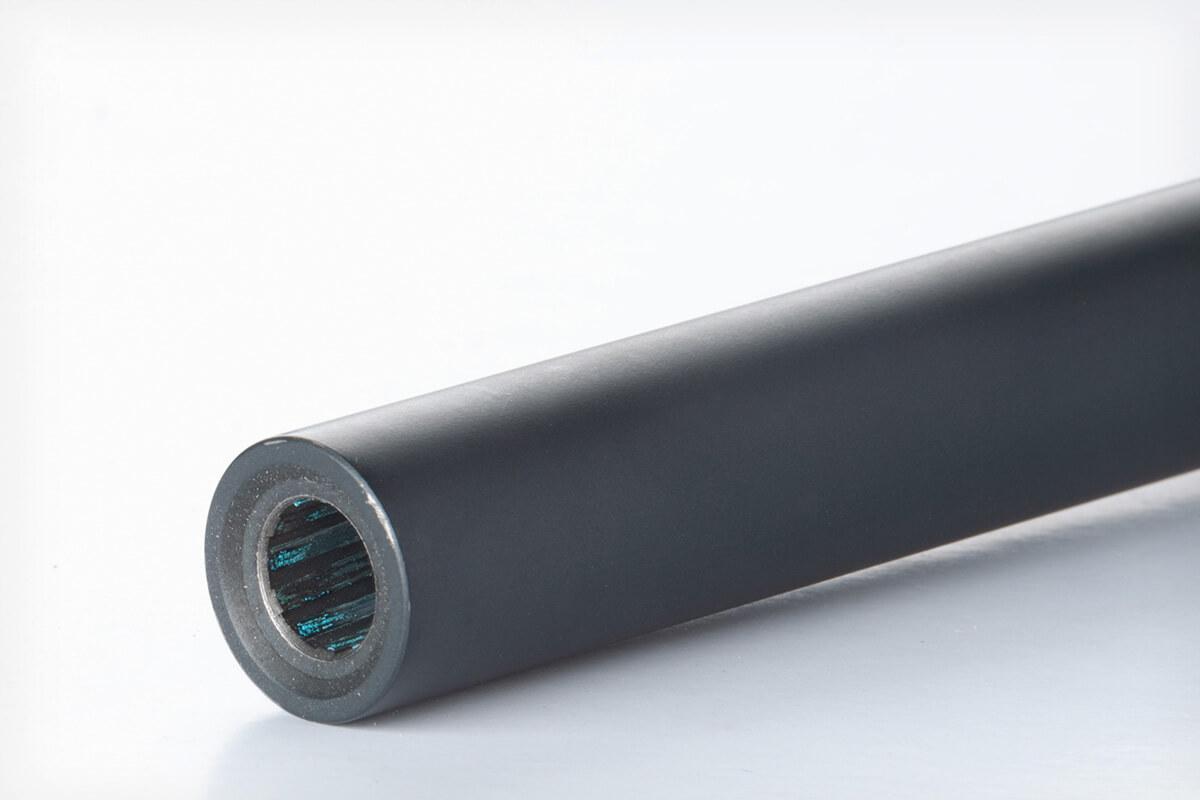

Always use a coated, one-piece cleaning rod. Coatings can be of Teflon or any other non-abrasive finish. They prevent the sides of the cleaning rod from wearing on the rifling. This is particularly critical around the chamber throat and rifling leade area, where the rod is most likely to contact firmly and for extended length. One-piece rods don’t have flexible joints that rub unevenly up and down against the rifling inside your barrel.

Carbon fouling can be removed pretty quickly, using cleaning patches on an appropriate-size cleaning jag. If you’re not worried about copper, use a classic mild solvent such as Hoppe’s No. 9 (properly pronounced, “Hoppy’s”). Brush with a bronze or nylon cleaning brush to loosen heavy carbon fouling and speed up the process if necessary. Hoppe’s is also an anti-corrosion agent, and a thin layer may be left in the bore as a protectant.

Copper fouling is more difficult. Because the process of removing copper automatically deals with carbon fouling as well, I generally just go straight after the copper.

Read more : Which Fabric Is Best For Tracksuit

Choosing a good copper fouling solvent is critical to the health of your bore. Traditionally, the active ingredient in most dedicated copper solvents is ammonia. It works great on copper, dissolving it in pretty short order. However, it can etch the steel in your barrel, too, particularly if it’s left in for more than 10 to 30 minutes, depending on the strength of the solvent.

Modern “gentle” copper solvents utilize chemicals that are harmless to steel, and won’t harm your bore even if left in for extended periods. They take a little longer to dissolve the copper, but it’s well worth it.

It’s difficult to drive home strongly enough the risk inherent to ammonia-based solvents. Once, while touring the Norma Ammunition facility in Sweden, I had the opportunity to visit with one of the company’s lead product managers. This gentleman had qualified for four consecutive Olympics during his career. In other words, he knew shooting, and he knew rifle barrels.

He told me he’d never use any ammonia-based solvent. I asked why. “It gets into the microfractures of the steel, and keeps on working, eroding,” he responded. “Eventually, like a crevasse in a glacier, the inside of those microfractures get hollowed out, leaving pockets in the steel.

“Plus, it’s very hard to get out,” my friend continued. “It migrates into every pore, and can’t just be wiped out with dry patches. And a coat of oil on top of it doesn’t neutralize it; it just traps it inside the pores of the steel.”

That wasn’t a pretty picture, particularly because I’d cleaned the bore of my favorite custom 6.5-284 rifle with an aggressive ammonia-based copper solvent just before flying to Sweden. “Can you get it out?” I asked.

“Yes…” came the response. “Flush your bore with hot water for 10 minutes every day for five days after using ammonia in it.”

I haven’t used ammonia-based copper solvent since. By the by, you can always tell an ammonia solvent by its sharp, astringent smell.

There are two copper-removing solvents I know of that work very well: Sharp Shoot’R offers two products, Wipe Out and Patch Out (foam and liquid), and Bore Tech has its Eliminator solvent.

Once your bore is clean and well dried out, you’ll want to lay down a thin layer of rust and corrosion preventative, particularly if you live in humid climates. Any quality gun oil will serve, but a thin, penetrating oil called Kroil is a magic ingredient for protecting and “seasoning” a bore. More on seasoning in a bit.

Barrel Cleaning Process

Read more : Which Succession Character Are You

My first step in cleaning a badly fouled rifle is to squirt Wipe Out foam in from the chamber end. Put a Ziploc bag over the muzzle to catch drips—it’s powerful soapy stuff.

About 30 minutes later I wipe the foam residue out. Most of the carbon fouling comes with it. If there’s significant copper in your bore, the liquid residue will be blue, as will your patch.

Next, I insert a bore guide to protect the chamber throat from wear, and push three to five patches wet with Patch Out solvent through, using a snug-fitting jag. Then I wrap a patch around a nylon brush that’s one bore size too small, wet it with Patch Out, and scrub the bore. I make about 20 passes from breech to muzzle and back.

Back to the jag, and patches wet with Patch Out. A half dozen or so should have the bore pretty clean, and patches should be coming out nearly spotless.

If not, you may have a really dirty bore. Not to worry; just start the process again. Even stubborn fouling should dissolve and scrub out after two or three cycles.

Once wet patches are coming out perfectly clean, I remove the bore guide and dry the bore out with a series of dry patches. When truly dry, the bore should get almost a rubbery feel, and the dry patches should become slightly more difficult to push through.

Finally, dampen a patch with Kroil (obtainable from some hardware stores and online) and push it slowly through the bore. Turn the patch over on your jag, presenting a fresh surface on the outside, and push it through again.

Kroil, like a fine seasoning oil applied to a high-quality cast-iron pan or Dutch Oven, gives the surface of the steel a non-stick attribute. Treat with Kroil after every cleaning, and your rifle will foul slower, and clean easier.

Wipe down your bolt body and bolt face with the Kroil patch, put a dab of bolt grease on the bolt locking lugs and cocking piece camming surfaces, and you’re done.

If you hunt humid climates, particularly in areas with salt-sea air, you’re ready for the field. However, the thin protective layer of oil in your bore can cause a slight point of impact shift and minimal change in velocity for the first shot or two, so if you hunt dryer, open-country areas, it’s worth firing a few fouling shots before heading afield.

With your bore clean and protected, your rifle is kept healthy and prepped to perform its best at the moment of truth.

Source: https://t-tees.com

Category: WHICH