Glove Integrity Testing has been a widely discussed topic in recent years, with numerous articles devoted to it. However, doubts still persist within the industry due to the lack of norms and clear guidance available. The importance of glove integrity testing was reiterated in Annex 1 to EU Guidelines to Good Manufacturing Practice in 2008. It stated that routine monitoring should include frequent leak testing of the isolator and glove/sleeve system.

Several statistical studies have been conducted by industry-specific associations to determine the frequency of this type of testing in the pharma industry. The results indicate that the test is typically performed before each batch of production. However, when it comes to performance requirements, the question remains: what hole diameter should one be able to detect?

You are viewing: How Well Can Gloves Hold Air?

The theoretical answer would likely be 1μm (the diameter of bacteria spores), but technological limitations make the practical answer much larger.

There are many methodologies available for testing glove integrity today, but few are automated and suitable for routine use. Additionally, finding equipment with performance qualification (PQ) for testing glove integrity is challenging due to the lack of test repeatability. Despite the many different methods available, the most commonly used method among users is the Positive Pressure Decay method, which follows the international standard ISO 14644-7 Annex E.5.

Read more : How Boxing Gloves Are Made

ISO 14644 Part 7 does not provide specific methodologies for Positive Pressure Decay. As a result, there are different interpretations of acceptance criteria. This leads to many questions about the performance of this method and the hole diameters that can be detected. One approach is to create a mathematical model describing an inflated glove with an orifice, which provides a formula relating hole diameter to expected pressure drop. However, this calculation is complex due to the varying elastic properties of different glove materials.

The glove materials available in the industry, such as Hypalon, Butadyl, Neoprene, and EPDM, have different reactions to stress and elasticity. Hypalon, in particular, poses a challenge to integrity testing due to its unique properties. Therefore, an experimental approach is necessary, taking into account thickness, size, and flange mounting.

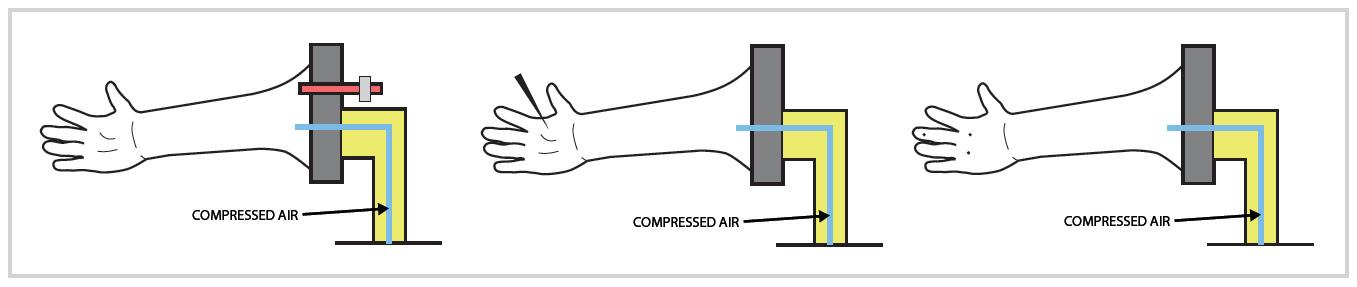

To perform the positive pressure decay method, there are different ways to conduct performance tests, including a calibrated hole on the flange, a needle inserted through the glove, or pinholes on the glove. Based on experience, the calibrated hole method is the most appropriate and precise. The Automatic Glove Tester, combined with the calibrated hole method, was used for collecting data on gloves of different sizes and materials available in the market.

To achieve qualified performance, several activities need to be performed, such as studying the pressure decay curve at various inflatable pressures for both the closed system (a brand new glove correctly mounted on the flange) and the open system (a brand new glove correctly mounted with a calibrated hole device connected).

Read more : How to Create a Strop Using a Suede Glove

From these curves, test parameters and acceptance criteria can be defined, including inflate pressure, stabilization time, testing time, and the ΔP limit. The goal is to find values that result in a significant difference between the pressure drop of the open system and the pressure drop of the closed system. The deviation of collected data should be as small as possible, and the accuracy of pressure transmitters must be considered.

With this method, a range of hole diameters can be detected by developing the correct test parameters. However, the detection limits are primarily influenced by the precision of the transmitters, statistical factors, and time constraints.

Through this method, a calibrated hole size of 100 μm has shown high reproducibility and a very low frequency of false positives. This means that an automatic glove tester machine can be easily validated. Smaller hole sizes may achieve lower detection limits, but they can impact reproducibility and increase the probability of false positives.

For more information and PQ protocols from this study, please request the data.

Source: https://t-tees.com

Category: HOW