There are so many factors you should consider when deciding on the right disposable glove: materials, properties, intended use, and cost. Grainger wrote a high-level, succinct article many years ago describing each factor. In this article, our goal is to contribute to the knowledge tree by diving deep into the factor of thickness.

You are viewing: How Is Mil Thickness Measured On Gloves

Read more : How Much Money Is Danny Glover Worth

In the disposable gloves world, thickness is measured in mils. One mil is equal to one one-thousandth of an inch (1 mil = 0.001″ gauge). For example, a glove that is 4mil will be 0.004 inches thick.

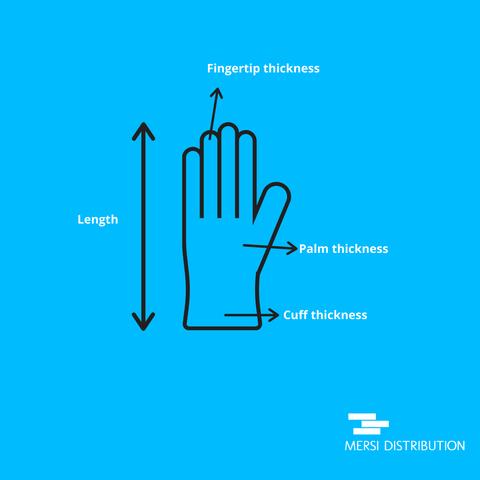

Measuring Thickness: Fingertip vs. Palm vs. Cuff

It is important to know that thickness figures can change depending on which part of the hand is measured. The most common type of thickness measured is finger thickness. Whenever you read “4mil nitrile glove” online, this is almost always the finger thickness. Finger thickness is most commonly used in the industry because the fingertips are always the thickest. The cuff is the second thickest area of the hand followed by the palm.

Read more : How To Buy Gloves

Here are some points of comparison for you to consider:

- Simply put, a thicker glove will provide more protection and durability while a thinner glove will provide more tactile sensitivity and dexterity.

- A thicker glove will have a longer breakthrough time than a thinner glove (breakthrough time: the time it takes to detect a substance inside of the glove when the outside is exposed to a chemical).

- A thicker glove, usually but not in every case, will have higher tensile strength than a thinner glove. Tensile strength is the resistance of a material to breaking under pressure.

- Thinner gloves tend to be more economical than thicker gloves, they require less space for storage, and they are better for the environment since less packaging material is used with them compared to thicker gloves.

Of course, deciding the right thickness depends on the industry you are in. Below are some specific industries and our thickness recommendations for each:

- Dental: 2mil – 4mil. Working with teeth, dentists require a glove to be thin enough to allow them enough dexterity and touch-sensitivity – especially considering precise maneuvers need to be made with tools. Omni 201 is a 2.76mil glove that works very well for dentists.

- Healthcare: 3mil – 5mil. As healthcare captures all kinds of providers, we think a 3mil – 5mil range is a fair recommendation. For procedures and settings where there isn’t such a great risk of harmful chemicals and fluids, and where greater dexterity is required, closer to 3mil will do. Omni 201, AmerCare Nitra-Med 4300, or Aurelia Amazing. Otherwise, you’re better off opting for a thicker glove such as Synguard. Synguard is offered in our new GroupBuy program and also individually.

- Foodservice: 1.5mil – 2.5mil. When working with food, you need a glove on the thinner end of the range in order to maneuver and carry out prep effectively. Vinyl and poly gloves are popular materials in the foodservice sector, however nitrile gloves also get the job done. For vinyl, we’ve got Safeko and Ripclear brands available on our store. For poly, we can vouch for the X3 series by Ammex.

- Industrial: 5mil – 7mil. Industrial use of disposable gloves, of course, requires thicker gloves due to the intensive nature of the work. Durability is an important factor, so materials such as vinyl and poly may not be your most effective options. It’s best if your disposable glove is rated ‘industrial grade’ and offers at least 5mil finger thickness. The GlovePlus brand is a best-seller if you’re looking for a thick, durable gloves for industrial use. It offers 6mil finger thickness and 5mil palm thickness.

Our recommendations are based on our experiences supporting customers in each of these segments. Be sure to consult your vendor for the best-suited disposable glove for your needs. While this article is a deep-dive into thickness evaluation, we recommend you consider all of the other factors as well when making your decision.

Source: https://t-tees.com

Category: HOW