Ever wonder about electrical safety gloves and if they are needed for electrical work?

You are viewing: How Often Should Voltage Rated Gloves Be Tested

How do they mitigate Arc flash hazards?

Why are they important in a PPE setup?

Then this blog might be of interest to you!

The article highlights the following topics related to electrical safety gloves such as:

- How are they classified?

- What do the color tags mean?

- How often should they be checked?

- Arc Flash Hazards within the working distance with gloves

Let’s dive right in!

FREE DOWNLOAD: DEFINITIVE GUIDE TO ARC FLASH STUDIES [ACCESS NOW]

Electrical Safety Gloves: Rating and Classification

Electrical safety gloves are key components for personal protective equipment (PPE or Arc Flash PPE) protecting your body against shock and arc flash hazards and can be considered the most essential component of the arc flash suit since the hands tend to be the closest extremity to potentially dangerous arc flash hazards. As such, having proper electrical safety gloves is paramount for protecting yourself. Insulating gloves may be assigned into three main categories:

- Standard Insulating Gloves are rubber gloves with very high dielectric properties which must be protected by protective leather gloves.

- Mechanical Insulating Gloves – are insulated gloves which have mechanical and impact protection against tears and punctures without the reliance or requirement of protective over gloves.

- ASTM D120 Gloves – American Society for Testing and Materials is the world’s largest source of standards (arrived at by voluntary consensus) for materials and goods.

CSA, NEC, and OSHA define any live circuit with a voltage above 50V to have an arcing potential and as such, electrical safety gloves are required to be worn. Furthermore, OSHA 1910.137(a) states that insulated gloves must meet the ASTM D120 standard.

Electrical Safety Gloves Classification

There are several different types of classes for insulated electrical gloves, which each fall into the separate categories discussed in the previous section. However, in general, gloves are classified based on their respective environmental resistance properties such as:

- Class- ranging from 00 to 4.

- Voltage level- ranging from 500VAC/750VDC to 36000VAC/54000VDC.

- Product Color- colored labels denoting class type ranging from beige to orange.

- Size-varies between 7-12 for male or female usage.

- Safety Classifications & Standards

- Type of glove which can be categorized as:

- Type I- non ozone resistant

- Type II- ozone resistant

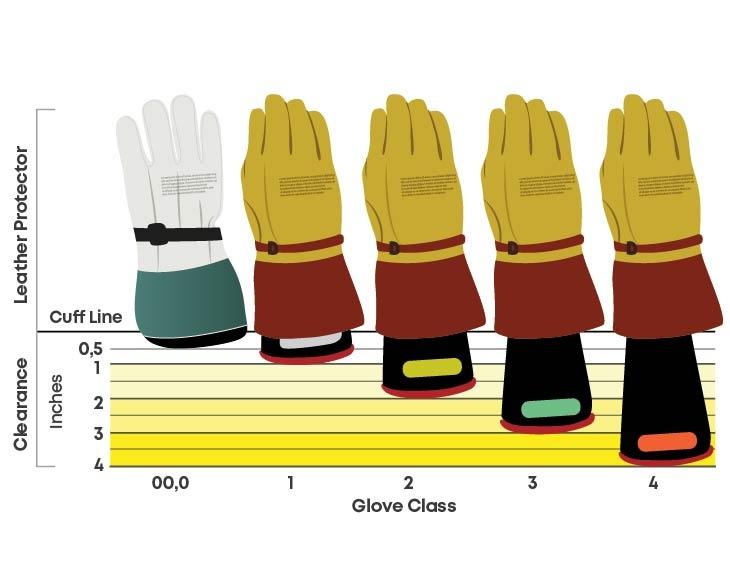

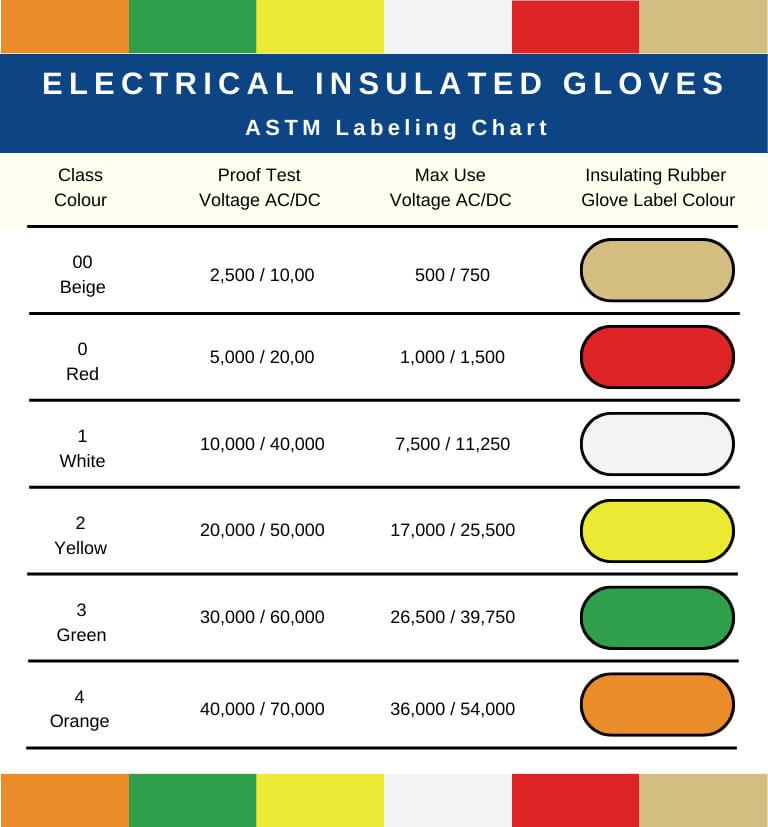

The table below breaks down the previously listed key designations in more detail.

Table 1: Electrical Safety Gloves Classification With Ratings, Sizes and Colors

Where the current glove class is maxed out at class 4 with most facilities usually utilizing class 00 and 0 gloves for lower voltage applications.

Furthermore, the electrical safety gloves are usually covered by a leather protector glove which is shown below:

These leather protector gloves have their own specifications as well but are typically made of cow/goat leather and are tested for several parameters including:

- Cut resistance (ANSI/ISEA Level A5 cut resistance);

- Hazard Risk Category (HRC) Arc Thermal Protective Value (ATPV) Lab testing in accordance with proper Arc Flash Level Rating (00 to 4);

- Thermal protection standard EN407 testing may include some if not all the following depending on the arc flash level rating (00 to 4):

- Burning Behavior Level;

- Contact Heat Level;

- Convective Heat Level;

- Radiant Heat Level;

- Large/Small Splashes of Molten Metal Levels.

Color Tags on Electrical Safety Gloves

Since Insulated electrical safety gloves can have a similar exterior color for all its classes, the key indicator in distinguishing between them lies with the color labels. As stated previously, the color for each class from 00 to 4 range from:

- 00-Beige;

- 0-Red;

- 1-White;

- 2-Yellow;

- 3-Green;

- 4-Orange.

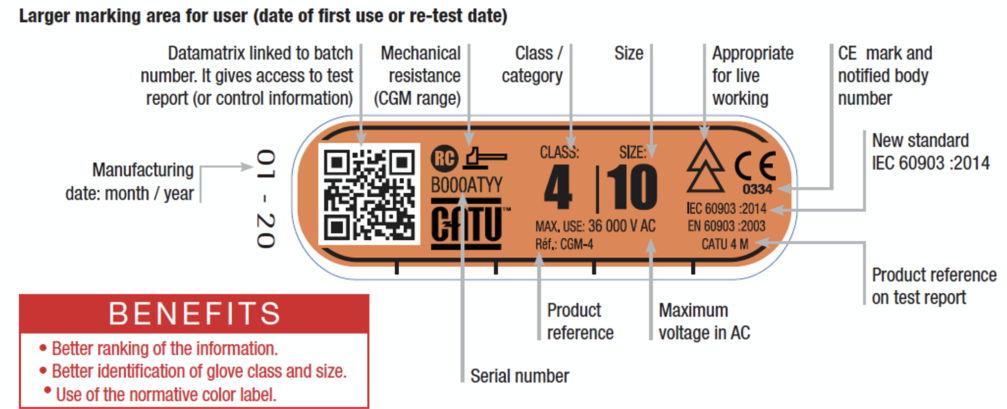

Each label is required to show key information regarding:

- Standard compliance;

- Serial number;

- Product reference;

- Class information;

- Physical size;

- Maximum voltage;

- Manufacturing, date.

The are two main classifiers which is shown in the figure below:

Figure 1: Class 4 label example

Class 00 Electrical Safety Gloves

Class 00 electrical gloves are commonly used in systems where the AC voltage does not exceed 500V. a typical Class 00 rubber glove is shown below:

Which have beige labelling as well as the manufacturer’s data.

Class 0 Electrical Safety Gloves

Read more : How To Clean Uoline Home Improvement Kitchen Gloves

Class 0 electrical gloves are commonly used in systems where the AC voltage does not exceed 1000V.

Most secondary levels of electric facilities usually do not exceed 600V on the secondary side of the transformer uncles you are dealing with heavy industry in which case higher class gloves are required. A typical class 0 glove looks like the following gloves:

Which have the corresponding red labelling designating class 0 as well as the manufacturers specifications.

How Often Should I Test My Voltage-Rated Gloves?

Electrical safety gloves and its protectors must be inspected for damage before use daily and anytime damage is suspected. Several things can happen to electrical safety gloves and its protectors including the following:

- Embedded foreign objects (metal slivers, splinters);

- Holes, punctures, tears or cuts;

- Ozone damage (fine cracks);

- Swelling, softening, sticky or hardening;

- Damage from chemicals.

Furthermore, insulating equipment must also be stored in a way that does not damage the material. The following items can cause damage:

- Temperature extremes;

- UV damage (from sunlight);

- Excessive humidity;

- Ozone (UV rays, arcing);

- Direct contacts to foreign materials such as petroleum products, baby powder, hand lotion, oils, etc.

Additionally rubber insolated gloves must be tested before first issue and every 6 months at an appropriate facility according to OSHA’s Table I-5, and also if:

- Insulating value is off;

- Any repairs have been done;

- Glove is used without protectors.

Arc Flash Hazards Within the Working Distance With Gloves

Up to now, we have discussed greater detail how electrical safety gloves can be categorized for both the rubber safety gloves and the leather protective gloves. However, it is important to note that although the gloves are rated for a certain incident energy level, they may not be adequately rated for their arc flash level when operating in close proximity to the conductor of a device that has an appropriate arc flash label. This is because an arc flash label takes into account the incident energy level based on working distance which typically ranges from 18 inches away from the potential arcing component (or higher). Furthermore, as the worker gets closer to the potential arcing source, the heat from the arc flash will increase exponentially which in turn increases the incident energy level.

Therefore, it becomes paramount to never ever work on live equipment. However, even with equipment being turned off, it does not change the fact that the circuit may still be energized as certain circuits may need a long time to deenergize (i.e. capacitor banks). This will potentially reduce the arc flash hazard, but it will not be zero.

The only way to truly verify if a circuit is deenergized is to do an absence of voltage test across the circuit. However, this is potentially very hazardous as it usually requires the individual to open the cabinets which will expose them to a potential arc flash hazard. There is specialized equipment which can do the test without the worker having to open the cabinet but these tend to be very expensive.

CSA Z462.2021 states in section 4.2.5(g) exception II for ‘adequately rated permanently mounted absence of voltage’ must meet the following requirements:

- The device must be permanently mounted and installed according to the manufacturers instructions and tests the conductors and circuit parts at the point of work.

- Proper labels should be employed to label the purpose of the device as testing for the absence of voltage

- The permanent device must test each conductor part for both phase-to-phase and phase-to-ground

- Satisfactory operation must be proven on the permanent device on any known voltage source before and after testing of absence of voltage.

Conclusion

I hope this article has helped to better explain electrical safety gloves.

Do you know anyone else that would benefit from this blog? Use the share buttons below to share the content.

If you have any questions, you can always reach out to me at [email protected].

- Category:

- ESP

- Arc Flash Study

- Training

- PPE

Source: https://t-tees.com

Category: HOW