Runout is a critical concept in precision machining and plays a significant role in ensuring the quality of machined parts. It refers to the variation in motion or position of a surface as a rotating part turns about an axis. The concept is often integrated with Geometric Dimensioning and Tolerancing (GD&T), a symbolic language used on engineering drawings and CAD models to define the allowable geometric variations in part geometry. Runout is one of the geometric tolerances specified in GD&T, and it is crucial to understand its implications to produce parts with high precision and accuracy.

You are viewing: What Is Run Out In Machining

In this guide, we will explore different aspects of runout, including GD&T runout, runout symbols, applications, and common issues related to runout in GD&T.

The Fundamentals: What is Runout?

Runout is a fundamental concept in the field of precision engineering and manufacturing. It is a term used to describe the deviation or inaccuracy that occurs when a rotating object, such as a spindle, shaft, or wheel, does not rotate perfectly around its central axis. In simpler terms, runout is the amount by which a rotating surface deviates from its ideal path during rotation. It is a critical parameter that influences the quality, performance, and functionality of machined parts and assembled products.

Example of radial and axial runout

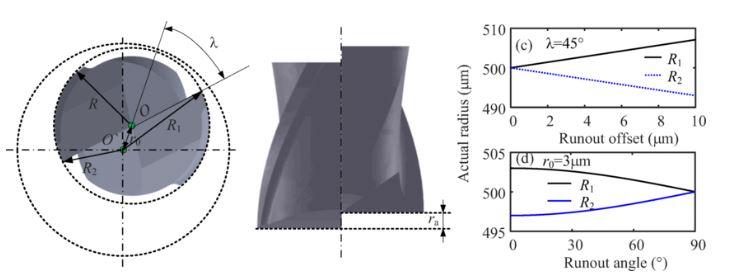

Runout can occur in any rotating object, and it is often considered a composite of two types of errors: radial runout and axial runout. These two components of runout affect different aspects of the machined part and can lead to various problems if not adequately controlled.

1. Radial Runout

Radial runout refers to the variation in the radial distance between the surface of the rotating part and its central axis. It is usually measured at a specific distance from the axis of rotation, and it affects the roundness of the machined part. Essentially, radial runout is the deviation from a true circular form experienced by a rotating part during its rotation. This deviation can cause the rotating surface to move closer to or farther away from the central axis as it rotates, leading to an out-of-round condition.

Read more : What I See Elevation Worship Lyrics

For example, consider a rotating wheel. If the wheel has radial runout, it means that as the wheel rotates, some points on the wheel’s surface will be closer to the axis of rotation, and some points will be farther away. This inconsistency can lead to uneven wear on the wheel and the surface it contacts, resulting in vibrations, noise, and reduced performance.

Radial runout is commonly measured using a dial indicator placed against the rotating surface at a specified distance from the axis of rotation. The part is rotated one full revolution, and the maximum and minimum readings on the dial indicator are recorded. The difference between the maximum and minimum readings indicates the amount of radial runout.

2. Axial Runout

Axial runout, on the other hand, refers to the variation in the axial distance between the rotating surface and a reference plane perpendicular to the axis of rotation. It affects the flatness and parallelism of the machined surface. Essentially, axial runout is the deviation from a true planar form experienced by a rotating part during its rotation. This deviation can cause the rotating surface to move up and down as it rotates, leading to an out-of-flat condition.

For example, consider a rotating disc. If the disc has axial runout, it means that as the disc rotates, some points on the disc’s surface will be higher, and some points will be lower relative to the reference plane. This inconsistency can lead to uneven contact with mating surfaces, resulting in vibrations, noise, and reduced performance.

Axial runout is commonly measured using a dial indicator placed against the rotating surface with the spindle in a horizontal position. The part is rotated one full revolution, and the maximum and minimum readings on the dial indicator are recorded. The difference between the maximum and minimum readings indicates the amount of axial runout.

Source: https://t-tees.com

Category: WHAT