If you’re not wearing cut-resistant safety wear on the job, you’re putting yourself at serious risk. Handling and operating blades, machine parts and sharp metal only adds to the danger. Thankfully, Milwaukee Cut Level E Touchscreen Safety Gloves (4932471424) are an incredibly dynamic, Level E cut-resistant glove designed to mitigate the effects of dangerous material.

What’s Included?

- 1 x Pair of Cut Resistant Gloves

Which Size Is Right for Me?

To find your perfect size, simply measure the circumference of your palm (ignoring the thumb area) and the length of your hand as indicated in the image below. Once you have your measurements, please consult the sizing chart below to find the correct size for your hand.

You are viewing: How To Find The Cut Level On Milwaukee Demolition Gloves

Glove Size Length of Palm (mm) Medium 191mm Large 197mm Extra Large 203mm

Milwaukee Free-Flex Protection Ratings

- 4X44E

Read more : How Old Was Donald Glover When He Started Rapping

EN 388 is a European regulation governing the sale of gloves used for safety and protection. It determines the gloves’ performance when used for protection against mechanical machinery by measuring the fabric’s abrasion, cut, tear and puncture resistance.

The EN 388 cut resistance test uses a single sharp implement to repeatedly pressure a glove in order to determine the amount of force required to cause visible and functional damage.

Standard Resistance Rating Abrasion Resistance Level 4 Cut Resistance N/A Tear Resistance Level 4 Puncture Resistance Level 4 ISO Cut Resistance Level E

Incredible Cut Resistance

Level E is the second highest rating available under EN 388. It means that a sharp implement would have to generate in excess of 22 newtons of force to rip through the tested fabric. This rating is the difference between a knife, blade, machine part or piece of metal tearing through your glove and your hand and it being jammed in the outer shell fabric of your glove.

Key Features and Benefits

- Incredible Level E cut-resistance rating

- Maximum abrasion, puncture and tear resistance under EN 388

- Touchscreen functionality for seamless use with smartphones and tablets

- Excellent grip performance thanks to double-dipped nitrile coating

- Proprietary knitting process provides all day comfort and high breathability

- Available in three different sizes for a guaranteed perfect fit.

Suitable Applications for Milwaukee 4932471424 Gloves

- Assembly

- Blade Handling

- Builders

- Carpentry

- Construction

- Joinery

- Knife Handling Applications

- Machine Operation

- Maintenance

- Roofing

- Scaffolding

- Sharp Object Handling

- Sheet Metal Handling

- Touchscreen Application

- Warehouse

- Woodworking

Affordable Heavy-Duty Protection

High-level EN 388 protection is hard to come by, especially at such a competitive price. Milwaukee Safety Gloves are manufactured to protect against the punctures, incisions and cuts that can so easily cause serious injury on building and construction sites.

A Complete Design Specification

Read more : How To Get Wood Glue Off Of Work Gloves

Milwaukee Cut Level E Gloves offer complete mechanical workplace hazard protection against abrasions, cuts, punctures and tearing. They have maximum Level 4 protection against abrasions, making them excellent for fast-paced packing departments, where constant contact is an issue.

What Does SMARTSWIPE Technology Do?

Tradesmen know how important touchscreen functionality is. No more removing your gloves to take a call or reply to messages. Sort through plans on your tablet, order parts online or take updated photographs for clients. Keep your gloves on and take care of business, no matter what your application.

What Are the Benefits of a Nitrile Coating?

Nitrile excels in damp and wet conditions. Because moisture and liquid are not always visible, the benefits of nitrile often go overlooked. It works tirelessly to suck and soak up particles that otherwise lay dormant on your palm, compromising your grip strength and causing accidents.

How Does a Double-Dipped Coating Help?

A double-dipped coating is exactly what it says. Two layers of nitrile combining to form a single, impenetrable outer shell that protects against moisture, grease and oil. The first layer creates a membrane-style layer and the second forms a slightly abrasive, grippy coating that aids with grip strength and stability.

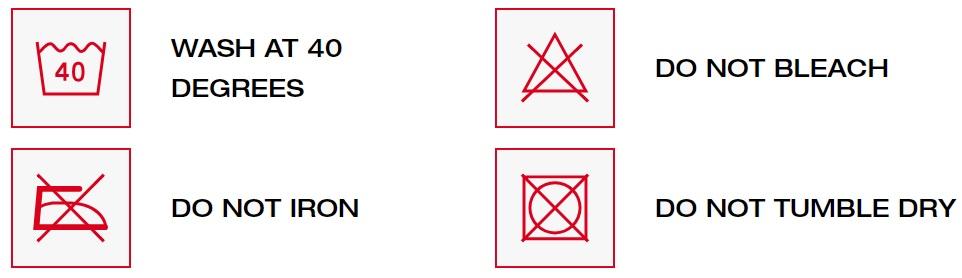

Washing Instructions

Additional Documentation

- Product Sheet

- Declaration of Conformity Statement

Source: https://t-tees.com

Category: HOW