What’s inside your Boxing gloves part 2

How the foam inside of the glove is constructed. To see part 1 click here.

You are viewing: How To Make Boxing Gloves Softer

The internal foam which most people will not see, is one of the most important parts of the boxing glove, you can have the best external glove material which may last 2 or 3 years but if the foams that have been used inside the glove are not good quality you may see the padding deteriorate within in 6 months, rendering the glove useless.

There are two main ways that manufacturers make the internal foams of a boxing glove, put simply they are

-

Machine made injected moulded foam or IMF.

-

Hand-made layered foam.

-

Layered foam, horse hair combined, ( not used very often now days)

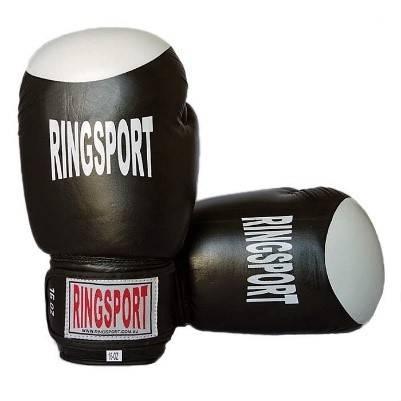

IMF or Injected molded foam below.

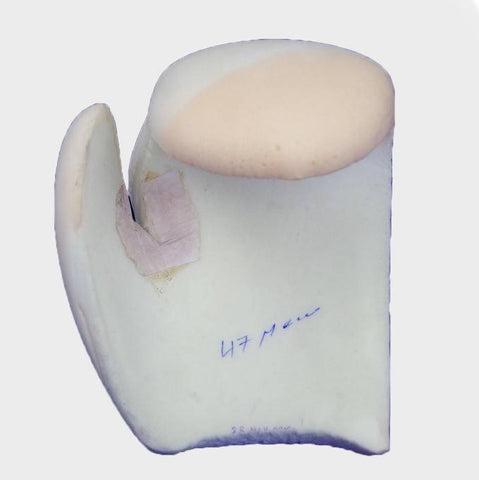

Hand made layered foam mould

INJECTION MOLDED INNER FOAM GLOVES

The gloves above are all Machine made injection moulded foam.

Machine injected foam or IMF as most distributors like to market it as, is foam that is injected into a pre made mold, left to dry and then placed into the outer cover of the glove. Many glove manufacturers are using these kind of molds now days. You can tell if it is a molded foam glove by the shape of the glove. They are usually quite rounded at the top in appearance see above picture. Another way to tell if it is a hand-made or IMF foam is to feel inside the glove with your hand, in a layered foam glove you will feel different layers of foam densities and if it is injected foam it will feel one solid piece of foam all the same density.

Injection molds are cheapest way too manufacture foam for inside boxing gloves, combine this with a cheap synthetic outer materials you can manufacture a boxing glove very cheaply. Injection molded foam boxing gloves, feel good and look good and are great for sparring, as they offer a lot of protection for your hands and especially for your sparring partner face and body.

Injection molds are usually 40mm to 50mm thick which offers very good protection for noses, cheek bones and offer a very safe glove for sparring when they are in relatively new condition. The foams come in different densities, some harder than others, the softer ones feel nice when you first put your hands into the glove and is easier to close your fist.

All AIBA approved boxing equipment that is licensed for amateur boxing bouts in the world, use injection molded foams for all fights, showing the safety aspects are well used.

Read more : How To Make A Glove That Launches Stuff

IMF or injected foam molds tent to wear out quickly, in some case very quickly if used for heavy bag work,. As a sparring only glove they may hold up for a year or so.

NEW

SLIGHTLY USED

WELL USED

UNUSABLE

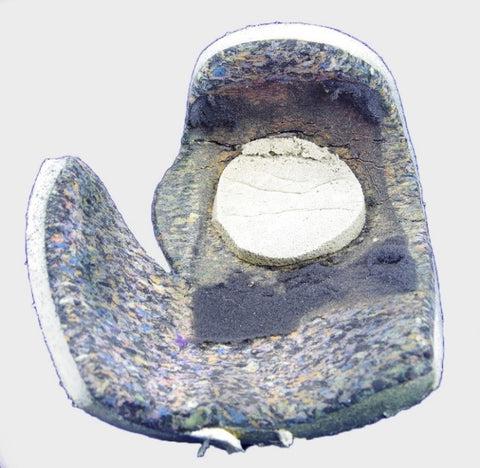

Above are injection molded foams in various stages of breaking down after bag work use.

The molds are good for a sparring glove but as for a bag glove they do not stand up to high intensity training, especially for heavy hitting boxers, most 65kg+ boxers will punch through the most IMF foams in less than 6 months if used for heavy bag work.

The foam break down will happen in a two ways, first you will start to see little lumps on the between the foam and the outer material of the glove surface, this is the pieces of foam starting the break away from the inside of the foam mould where your fist knuckles are starting to dig into the foam.

The other thing that can happen is the mold can crack across the inside of the foam and eventually break usually where the foam gets a little thinner around the upper finger area.

Pros

- Good thick safe padding for sparring.

- Good knuckle protection.

Cons

- Foam tends to break down.

- Durability is not good, compared to layered foam molds.

- Foam may crack and split prematurely.

HAND MADE LAYERED INNER FOAM GLOVES

Rogue 16oz training gloves above.

Read more : How Many Yards To Make Fingerless Gloves

Hand Made Layered foam gloves are made by combining different density layers of foam together to make the correct density mold for the type of boxing glove needed, whether it be a sparring glove a bag glove or a glove that can be used for both bag work and sparring.

In the perfect world you will have separate sparring and bag work gloves, your sparring gloves needs to have a softer outer foam to provide protection to you sparring partner and you bag gloves would have a higher density outer foam to make the glove more durable.

Hand made foam gloves have range of different qualities of foam that may be in gloves and the cost will vary, depending on which type of foam that is used. Below is a basic layered foam mould which is a standard for most gloves made in Pakistan.

- The outer foam is a latex rubber foam

- The coloured foam is a compressed foam similar to underlay

- The black foam is a sponge foam for initial hand comfort.

- Under the black foam is a slightly higher quality foam that is placed there to stop fist contact with the compressed foam which tends to break down is not protected.

This sort of foam mould is from a training glove rather than a sparring glove as the outer foam is very thin and quite firm.

This foam mold below is the same sort of mold as above that has been use for a year or so, it has held up well, the black sponge foam has worn away and revealed the inner latex foam. The glove is still usable but should be replaced soon.

This kind of mold is basic cheap version of hand made foam, this style is found in most of the layered foam boxing gloves on the shelf at sports stores and most martial arts stores. It is quite good and durability is fair, they could last a couple of years with two nights week training

There are better moulds available which are much more durable and comfortable.

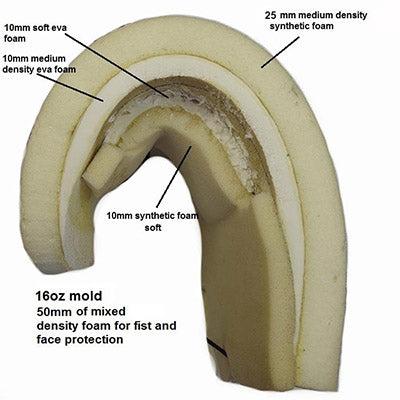

This mould below is an example of a 4 layer higher quality hand made mould, the fourth layer is between the central eva and the inner layer

- The outer layer is a synthetic sponge foam.

- The central layer is an medium density EVA foam which is very durable and almost never breaks down.

- The inner foam is a high density synthetic foam which is very comfortable.

Under the inner foam is a 10mm extra foam sheet for extra protection for the knuckles

The above foam is from a 16oz Ringsport Rogue training glove and is 45mm thick, this glove is good for bag work, pads and partner work and sparring glove as the outer foam is thick enough for full contact sparring. The 10oz and 12oz model has a thinner outer layer for extra feel on the bags or pads

The mould below is a very high quality hand made foam mould ideal for bag work, pads and full contact sparring, this type of mould is found in high end gloves like Thailand made brands such as Top King, Twins and the Ringsport super pro range.

- The outer foam is a medium density synthetic foam up to 25mm thick.

- Then a 10mm wedge over the knuckle area.

- A 10mm high density EVA foam through out the mold.

- The inner comfort foam is a high density 10mm synthetic layer.

High quality Ringsport super pro 16oz

LATEST INNOVATION IN BOXING GLOVE FOAMS

Some boxers especially professional boxers who are pounding bags and sparring a lot tend to get hand and knuckle issues, to which some boxer use gel padding in, or under their hand wraps to create a softer impact zone. While these gel pads are very helpful they do tend to make the hand and wrap combination quite a lot bigger and can hard to get into the glove. To solve the problem Gel lined inner foams that have been created by Ringsport, the gel needed to help alleviate the knuckle soreness has been placed inside the glove foams. This creates the most comfortable glove you can imagine, with a combination of 6 layers of foams the glove is almost a perfect sparring or training glove.

THE NEW SUPER PRO GEL INNER FOAM

Source: https://t-tees.com

Category: HOW