Do You Have A Stuck Glove Box?

Overview

If you’re willing to put a small hole in the glove box instead of cutting the loop, this is how to do it.

You are viewing: How To Open A Glove Box That Is Jammed

Procedure

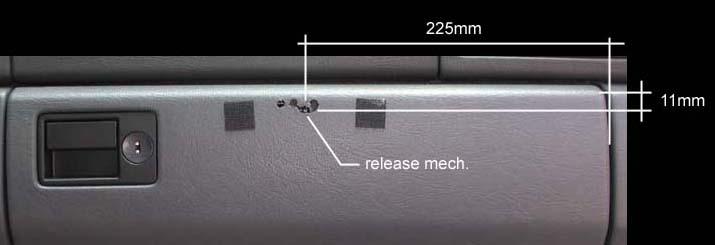

The measurements: 225mm from the right hand side of the glovebox, and 10-11mm from the top edge of where the face of the glove box starts. drill a small hole (1/8″), and pull on the handle while pushing in and up with the coat hanger. it might take a few tries to hit the release, but it doesn’t take much to pop it loose.

Step 1

Once you are able to get the glove box open and remove the screws that hold the face to the backplate, you’ll see the inner workings as shown above. the mechanism itself contains a lot of small parts, but the piece that’s probably broken is the release. there is a small pin that protrudes from the right side of the actuator, and most likely it has been broken off. Once you are disassemble everything and are able to see where it’s been snapped off, that’s the point at which you need to drill a hole to insert the screw. i don’t know the size of the screw, but it’s very small, possibly 3 /32″ by about 3/4″. once the hole is drilled, you may have to wiggle the bit to get the screw to start threading it in. i did not tap it, as the actuator is made of a pretty soft metal.

Conclusion

Read more : How To Close A Glove Box On Range Rover 06

All of the pieces are very small, and careful notation of how everything comes apart is a necessity.

Comment on this Stuck Glove Box Fix procedure

This Glove Box Fix By Yeagermeister

Comments

wolfclan » Thanks for the info and pictures on this.

I did choose to drill a hole in mine and because of your precise directions and measurements I was able to drill exactly where you said however I used a smaller bit so there was less damage. I also used an ice pic instead of a coathanger. I found this worked very well. As a result there is just a very tiny hole that is not too noticeable.

I did the fix as you described with a slightly different approach. I removed the release mechanism as I found it easier to work on and drill the hole. I installed the screw from the other side then cut off the head.

Read more : How To Crochet 1859s Gloves

There is one slight catch though, There was a pin and spring on the underside of the mechanism that is not visable until you remove it from the door. When I removed it I could feel the preasure of the spring release from its’ position which I was unable to see. I could not remember how the spring and pin on the underside re-attached nor could I figure out what it does so I installed everything without it just to see if everything works. Guess what it all works perfectly without the mystery pin and spring.

steveb » Thank you so much for the fix. Instructions spot on. I used a 2mm drill which left negligible marking. For the pin I used a 3mm scred, drilled and tapped. I cut the head off and loc-tited it in just to be sure.Thanks again,Steve

malum » Thanks so much for the info.Couple of points:If you have a right hand drive the distance for the from the edge to the drilling point for the hole is reversed, rather than being in the same place as for a left hand drive.

I also put my screw in from the opposite side from yours (nothing to do with LHD or RHD) as I couldn’t quite work out where your screw went and how it worked from the pictures. my screw directly replaces the pin that was snapped and screws into a hole I drilled in the actuator at the point where the pin had snapped off.

I filled the hole in the front with some filler which I will dab in with a dark grey marker or some paint.

Thanks again, great stuff saved me some serious bother.

Source: https://t-tees.com

Category: HOW