The equivalent length of a duct fitting is a crucial parameter in designing efficient duct systems for heating, ventilation, and air conditioning (HVAC) applications. In this informative guide, we will delve into the meaning and significance of the equivalent length of a duct fitting, explaining how it affects airflow and energy efficiency. Whether you’re an HVAC professional or simply interested in understanding the principles behind effective duct design, this article on “what does the equivalent length of a duct fitting mean” from Chembaovn.com will provide valuable insights to enhance your knowledge.

Key Takeaways The equivalent length of a duct fitting represents the length of a straight duct section that would cause the same pressure drop as the fitting. It is essential for determining the total equivalent length of a duct system, which is crucial for proper airflow calculations. Calculating the equivalent length involves considering the fitting type, size, shape, and associated fittings or accessories. Factors such as the duct material, airflow velocity, and friction losses also impact the equivalent length. Understanding the equivalent length aids in optimizing duct design, reducing energy consumption, and ensuring efficient heating, ventilation, and air conditioning (HVAC) systems.

You are viewing: What Does The Equivalent Length Of A Duct Fitting Mean

I. Understanding Duct Fittings

Importance of Properly Designed Duct Fittings

Duct fittings play a crucial role in HVAC systems, as they allow for the smooth and efficient flow of air. However, determining the correct size, shape, and type of fitting is essential for maintaining optimal airflow. The equivalent length of a duct fitting is a key parameter that directly impacts the pressure drop and energy consumption of the system.

By understanding the equivalent length, HVAC professionals can design duct systems that minimize the pressure drop and reduce energy waste. Properly sized and shaped fittings also ensure that air flows smoothly through the system, improving overall efficiency and preventing issues such as turbulence and noise.

- What Does It Mean When You Dream of the Devil?

- What Does It Mean When You Hit a Bird?

Types of Duct Fittings

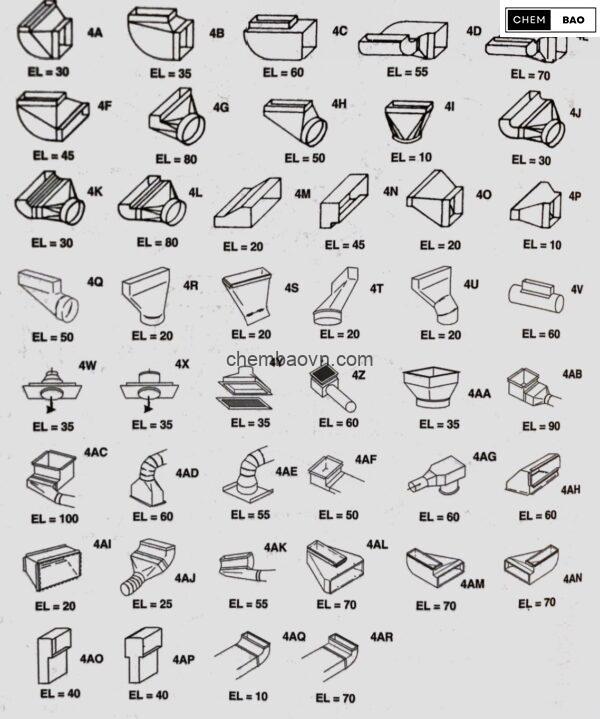

Duct fittings come in various shapes and sizes, each serving a specific purpose in the overall ductwork system. Some common types of duct fittings include elbows, tees, reducers, transitions, and dampers. Each fitting introduces its own pressure drop and affects the airflow characteristics of the system.

Elbows, for example, redirect the airflow, causing turbulence and increased pressure drop. Reducers, on the other hand, facilitate a change in duct size, which can impact air velocity and pressure. By understanding the characteristics and performance of different fittings, HVAC professionals can make informed decisions to optimize airflow and energy efficiency.

- What Does “SP” Mean Sexually?

- What Does “WBY” Mean on Snapchat?

Calculating Equivalent Length of Duct Fittings

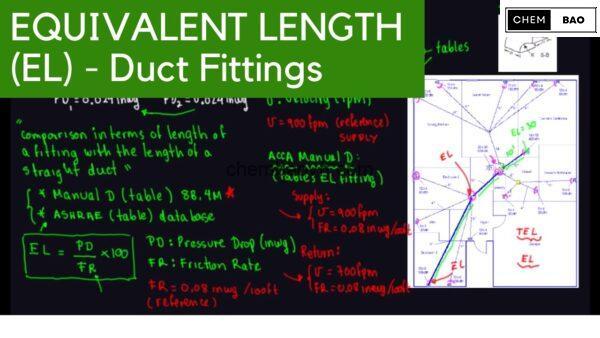

The equivalent length of a duct fitting is calculated based on the size, shape, and type of fitting, as well as any additional accessories or fittings that may be present in the system. The equivalent length represents the length of straight duct that, if used instead of the fitting, would cause the same pressure drop.

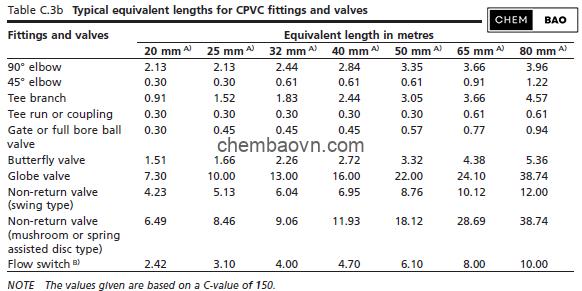

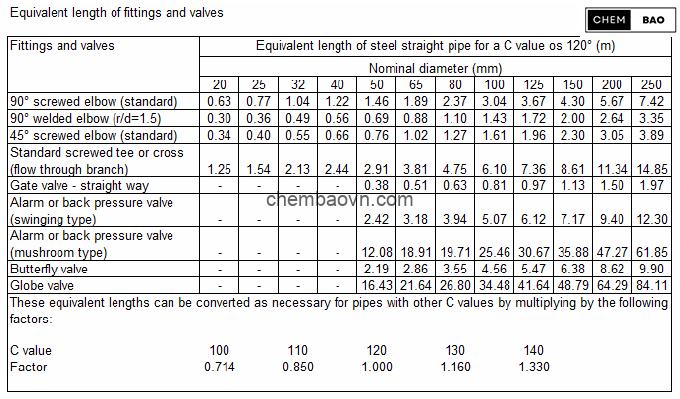

Read more : What To Wear To A Confirmation

Equations and charts are available to help HVAC professionals calculate the equivalent length for various fittings. These calculations consider factors such as friction losses, airflow velocity, and the characteristics of the fitting itself. By accurately determining the equivalent length, professionals can ensure accurate and efficient duct system designs.

- What Does “L-U” Mean in Texting?

- What Does the Number 17 Mean in Scripture?

II. What is Equivalent Length

The Definition of Equivalent Length

The equivalent length of a duct fitting refers to the length of a straight duct section that would produce the same pressure drop as the fitting itself. In other words, it is a way to measure the effect of a fitting on the airflow in terms of an equivalent length of straight duct. This concept is essential for designing effective duct systems, as it allows engineers to accurately account for the pressure losses caused by various fittings.

Why Equivalent Length Matters

Understanding the concept of equivalent length is crucial in HVAC system design. The total equivalent length of a duct system directly affects the system’s performance, air distribution, and energy efficiency. By accurately calculating the equivalent length, engineers can ensure that the duct system is properly sized and balanced, with the right amount of airflow delivered to each space. This helps maintain consistent temperature control, minimize pressure drops, and reduce energy consumption.

III. Calculating Equivalent Length of Duct Fittings

Determining the Equivalent Length

Calculating the equivalent length of a duct fitting is a crucial step in designing an efficient duct system. The equivalent length represents the additional straight duct length that would produce an equivalent pressure drop as the fitting itself. It helps determine the total equivalent length of the entire duct system, which is essential for accurate airflow calculations and system optimization.

To calculate the equivalent length, several factors need consideration:

- The type of fitting: Different fittings have varying resistance to airflow, resulting in different pressure drops.

- The size and shape of the fitting: Larger or more complex fittings generally create more resistance to airflow and higher pressure drops.

- The presence of associated accessories: Additional components like dampers or filters may impact airflow and affect the overall pressure drop.

These factors are used in empirical formulas or tables provided by industry standards like ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) to determine the specific equivalent lengths associated with each type of fitting. By summing up these individual lengths with other straight duct lengths, one can obtain an accurate measurement for calculating airflow rates and optimizing HVAC systems accordingly.

Example Calculation

“Consider a 90-degree elbow with a radius equal to half its diameter. According to industry data, this particular elbow has an approximate equivalent length equal to 30 times its diameter – making it quite significant compared to other fittings. If we assume a standard 6-inch diameter elbow is used in our design, then its calculated equivalent length will be approximately 180 inches or 15 feet.”

This example highlights how even a single component like an elbow can significantly contribute to the equivalent length of the duct system. By accurately calculating and considering the equivalent lengths of all fittings, designers can optimize the airflow distribution, reduce energy consumption, and ensure efficient HVAC performance throughout the system.

IV. Importance of Equivalent Length in Duct System Design

Read more : What Time Is 15 28

When designing a duct system for heating, ventilation, and air conditioning (HVAC) applications, understanding the importance of equivalent length is crucial. The equivalent length of a duct fitting refers to the length of a straight duct section that would cause the same pressure drop as the fitting itself.

Affects Airflow and Energy Efficiency

The equivalent length plays a significant role in determining the total pressure drop within the duct system. By accurately calculating the equivalent length of each fitting, it becomes easier to estimate the overall pressure loss and design the system accordingly. Proper airflow distribution is essential for efficient HVAC operation, ensuring that each area receives the required amount of conditioned air.

Additionally, the equivalent length affects energy efficiency. If the duct system’s equivalent length is not correctly considered, it can lead to excessive pressure drops, causing the HVAC system to work harder to maintain the desired airflow. This, in turn, results in higher energy consumption and increased operating costs.

Enables Proper Airflow Calculations

The equivalent length of duct fittings is vital for accurate airflow calculations. By incorporating the equivalent length in the design process, designers can calculate the total equivalent length of the duct system. This information allows them to determine the appropriate fan size, select the right duct dimensions, and ensure that all areas receive the required airflow for optimal comfort and performance.

Without considering the equivalent length, the calculated airflow rates may not be accurate, leading to inadequate cooling or heating in certain areas or excessive airflow in others. Therefore, understanding and correctly accounting for the equivalent length is essential to achieve a well-balanced and efficient HVAC system.

Affects Duct System Performance

The choice of fittings and their equivalent length impacts the performance of the entire duct system. Improper selection or inaccurate calculation of the equivalent length can lead to improper air distribution, increased noise levels, and decreased system efficiency.

By considering the equivalent length, designers can optimize the duct system layout, minimize pressure losses, and ensure a proper balance between supply and return airflows. This results in better temperature control, reduced energy waste, and improved overall system performance.

V. Conclusion

In summary, understanding the equivalent length of a duct fitting is crucial for efficient HVAC system design and optimization. By calculating the equivalent length, designers can accurately assess pressure drops and airflow restrictions caused by fittings, ensuring proper sizing and maintaining optimal airflow. Factors such as fitting type, size, shape, associated fittings or accessories, duct material, airflow velocity, and friction losses all contribute to the total equivalent length. By considering these factors and using practical examples, designers can make informed decisions to improve energy efficiency and reduce operational costs. Incorporating the concept of equivalent length into duct design supports a comfortable indoor environment while minimizing energy consumption. With this knowledge, HVAC professionals can confidently and effectively design duct systems that meet the needs of their clients and enhance overall system performance.

Source: https://t-tees.com

Category: WHAT