How does Inverter Technology Work (in welding machines) ?

In simple terms, an inverter is an electronic system for voltage regulation. In the case of an inverter welding machine, it converts AC power supply into a lower usable output voltage – for example, from 240V AC supply to 20V DC output.

You are viewing: What Is An Inverter Welder

Inverter-based devices use a series of electronic components to convert the power – in contrast to conventional transformer-based devices which depend primarily on a single large transformer to regulate the voltage.

An inverter works by increasing the frequency of the primary power supply from 50Hz up to 20,000 – 100,000Hz. This is done through the use of electronic switches which turn the power on and off extremely quickly (up to 1 millionth of a second). By controlling the power supply in this way, before it enters the transformer, the transformer size can be very significantly reduced.

What are the benefits of using Inverter Welders?

Read more : What Does A Circle In A Triangle Mean

Inverter-based products offer many advantages over conventional transformer-based devices:

- Weight and Size: This is the most significant and impressive advantage an inverter welder has over conventional machines. For example, an inverter weighing less than 5kg, smaller than a suitcase and able to be comfortably slung over your shoulder, can have a comparable output capacity to a 50kg transformer-based machine.

- Efficiency: Quality inverter machines, such as the Weldforce inverter welder range, will have an efficiency rating of about 80-90% while conventional welders have a significantly lower efficiency of about 50%. This is due to the fact that the larger transformers in conventional machines have greater resistance and therefore lose a significant amount of power (or energy) through heat dissipation.

- Use of Generator Power: Being very efficient means that using generator power is much more viable with inverter welders, which can be operated on smaller portable generator sets – something that is often not possible with traditional transformer machines. It should be noted that there are risks involved with using generators power – for more information, read our article on generator use with inverter welders.

- Duty Cycle: Generally much higher duty cycles are achievable with inverter-based machines, again due to the difference in transformer size. Although the smaller components in an inverter machine heat up quickly, they can be cooled much easier and faster. In conventional “transformer” welders, however, the components are much bigger and therefore tend to store heat and take longer to cool.

- DC Output: Many conventional “transformer” MMA (stick) welders only have AC output, which means they are limited in the types of electrodes they can weld with. However, with inverter-based machines the current is much more easily rectified into DC which means they are able to weld a wide range of different welding electrodes. It also means that some MMA (stick) inverters are also suitable for DC TIG welding, which is not possible with conventional AC machines.

- Performance: The performance of quality inverter-based welders is substantially superior to that of conventional welders. This is especially noticeable with MMA (stick) welding where operators find that welding is far easier and they do not have to ‘fight’ the arc. This is mainly due to the ability of inverter machines to have higher open circuit voltages and incorporate features such as Hot Start, Anti-Stick & Arc-Force. A prime example of this is welding of thin materials: using a conventional stick welder this is notoriously difficult if not impossible, but with inverter machines like the Weldforce range which have infinite amperage adjustment and a very stable arc, the output can be turned down very low so that it will weld say 1.6mm sheet metal or tube section with relative ease & control.

- Functions: The electronics of inverter machines lend themselves much more easily to the ability to incorporate additional functions (such as TIG mode) and to make existing functions more controllable.

What is IGBT Inverter Technology?

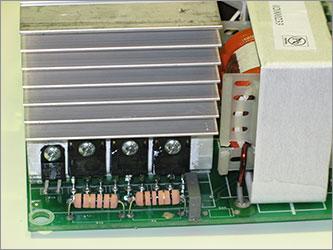

The acronym IGBT stands for “Insulated Gate Bipolar Transistors”. These are high-speed switching devices used in all Weldclass Inverter welding machines which facilitate the voltage regulation.

Some inverter machines use older MOSFET technology / transistors. IGBT technology offers significant advantages over MOSFETs – perhaps the most important advantage is that IGBTs are less vulnerable to mains and generator power fluctuations making them much more reliable and less prone to damage or failure.

IGBTs

More articles on inverter welders;

Read more : What Is Authidmob.com

What is duty cycle and how is it calculated?

Using Generators to power Inverter Welders

All welding machine articles

While all care has been taken, Weldclass accepts no responsibility for any inaccuracies, errors or omissions in this information or links and attachments. Any comments, suggestions & recommendations are of a general nature only and may not apply to certain applications. It is the sole responsibility of the user and/or operator to select the appropriate product for their intended purpose and to ensure that the product selected is capable of performing correctly and safely in the intended application. E.&O.E.

Source: https://t-tees.com

Category: WHAT