Two months ago, we covered testing potentiometers, such as TP and APP sensors. Both of those sensors could cause driveability complaints, transmission shift problems, and cause the MIL to light.

This month, we’ll cover pressure sensors. MAP and BARO sensors were more common prior to 1996 with the exception of a few manufacturers. Around the introduction of OBD-II, mass airflow sensors (MAF) became the industry standard.

You are viewing: What Should A Map Sensor Read In Hg

A few manufacturers stuck with the speed density (non-MAF) systems. Honda and Chrysler are a couple OEs that seemed to stay with speed density systems over the more popular MAF sensor driven fuel management systems.

Regardless, pressure sensors have been making a comeback, especially with the introduction of GDI and the proliferation of turbocharged engines. Remember, a MAP sensor is really no different than a boost pressure or barometric pressure sensor. This topic warrants some discussion because we’ll be seeing more pressure sensors in the years ahead.

Theory

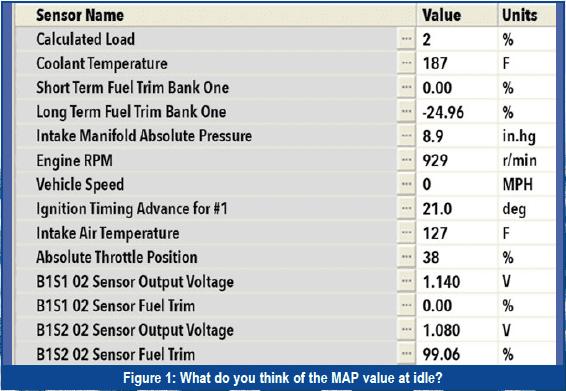

Before we move forward with pressure sensor diagnosis, we need to address some commonly misunderstood theory. I regularly teach a class on scan data analysis. One of the very first slides I show is from a Jeep that’s surging (figure 1).

The data needed to find a diagnostic direction during class is obvious in the slide. But, when I pose the question “What do you see in the data?” I always get some confusion on one PID. To be fair the vehicle is idling in the bay. What do you see?

Usually the attendees pick out the fuel trim numbers, which are definitely an issue. But the actual cause of the poor fuel trim numbers is a faulty TPS. The false data from the TPS is causing the PCM to over-fuel the engine.

In turn, the oxygen sensors report a true rich condition and the PCM responds by backing off fuel delivery. But the data PID that always generates discussion is the Intake Manifold Absolute Pressure PID, which reads 8.9 in-Hg at idle.

I understand the confusion. Think of what you know about intake manifold pressure and a conventional vacuum gauge: Wouldn’t you expect the vacuum gauge to read 18-22 in-Hg at idle? I hope so.

And if you connected a vacuum gauge to this vehicle, you’d get an acceptable reading of 20 in-Hg. So why does the scan tool display 8.9 in- Hg? For that, you need to understand pressure, vehicle, and tool display.

The confusion here relates to how a vacuum gauge displays vacuum versus how manufacturers and scan tools display pressure data. There are two variables to keep in mind: gauge pressure versus absolute pressure, and the units of measure being displayed. Unit of measure is the easiest to address so we’ll attack that first.

Units of Measure

We’re all familiar with SAE and metric measurements when it comes to length. For example, miles vs. kilometers. Even better, you probably know that a 1/2-inch wrench is about the same as a 13-millimeter one. Those conversions are easy.

Read more : What Does The Bumble Bee Symbolize

When it comes to pressure or vacuum, you might be a little less versed. You can easily solve these conversion issues by plugging numbers into a calculator or searching them on the web. After a while, you’ll memorize numbers like 29 in-Hg and 99 kPa and associate them with barometric pressure.

Of course, these numbers vary based on your altitude. In addition, they’re absolute. That brings us to our next point: gauge vs. absolute.

Gauge Pressure vs. Absolute Pressure

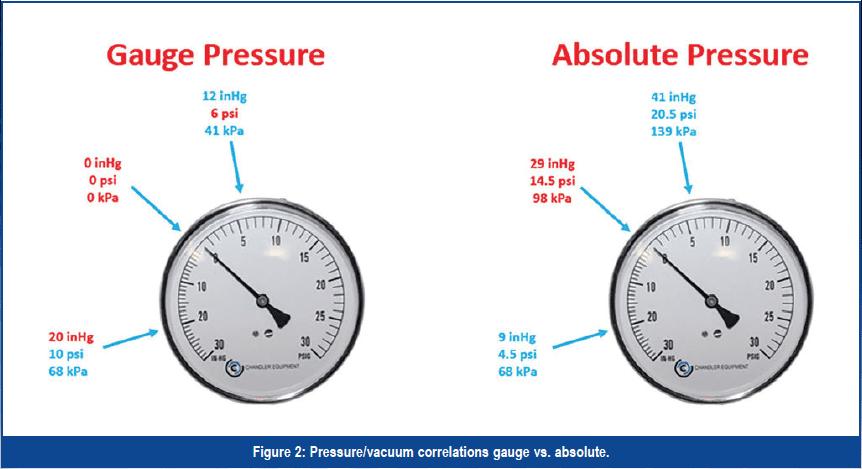

In the case of the Jeep, the barometric pressure PID reads about 29 in-Hg. At idle, the MAP sensor is reading about 9 in-Hg.

First, the scan tool is reporting the barometric pressure as if we were watching the weather on the evening news. What I mean is the meteorologist tells us that the barometric pressure is the true measurement of atmospheric pressure that is pressing down on our bodies. If that’s the case, then a BARO reading that matches the actual pressure of the atmosphere is correct.

Second, if we start the engine, the intake manifold pressure will be lower than atmospheric pressure, or a vacuum. Our Jeep pressure is about 20 in-Hg less than atmospheric pressure.

So 29 in-Hg (BARO) minus 9 in-Hg manifold pressure equals 20 in-Hg difference. Or 20 in-Hg below atmospheric pressure, which is exactly what we would expect from an idling engine.

What this vehicle or scan tool is doing is displaying pressure and vacuum as absolute. With some conversion, you can relate the pressure/vacuum readings to what you’re used to seeing on a conventional vacuum gauge.

Exploration of the Variations

If the Jeep were to display scan data in the gauge pressure method, the BARO reading would be 0 in-Hg and the idle pressure/vacuum would be displayed as 20 in-Hg. Just what you’d expect if you had a vacuum gauge connected to an intake manifold vacuum source.

Let’s pretend for a moment that this Jeep has a turbocharger. Under a full-boost situation, the MAP sensor might read 41 in-Hg. What this actually means is 29 in-Hg BARO plus 6 PSI of boost (or 12 in-Hg boost) equals 41 in-Hg manifold pressure.

How did I come to that conclusion? One PSI is the same as two in-Hg. That means 12 in-Hg above atmospheric pressure is equal to 6 PSI above atmospheric pressure, or 6 PSI of boost.

A General Motors vehicle might display 99 kPa BARO and 31 kPa MAP at idle. In that case, GM is displaying absolute pressure in a metric absolute format. It’s important to know the difference to avoid inaccurate diagnosis of a pressure sensor or a misunderstood pressure reading that leads down the wrong diagnostic path.

The easiest way to get a grasp on how a particular vehicle’s data appears is to look at the MAP reading with the key on, engine off (KOEO) and then start the vehicle to see where the data PID moves.

The easiest way to get a grasp on how a particular vehicle’s data appears is to look at the MAP reading with the key on, engine off (KOEO) and then start the vehicle to see where the data PID moves.

Read more : What Is So Rare As A Day In June

If KOEO MAP (or BARO) reads a positive number, then the scan tool is most likely displaying data in absolute. Once the vehicle starts, if the stabilized idle pressure is a lower number, you’ve confirmed an absolute reading.

For example, if the KOEO MAP reading is 29 in-Hg, 99 kPa, or 0.99 BAR, then the tool is displaying pressure as an absolute. Starting the vehicle, assuming 20 in-Hg vacuum at idle, should create an idle reading of 9 in-Hg, 31 kPa, or 0.31 BAR respectively. Conversely, a KOEO MAP reading of 0 in-Hg, 0 kPa or 0 BAR would indicate gauge pressure and the idle readings would move down from there.

Figure 2 may help relate all of these pressure values: The red labels are the values you’re most familiar with. The light blue labels are equivalents that might throw you curve balls.

Notice that the left gauge is labeled as if it were a conventional gauge that you’ve connected to a vacuum source on the intake manifold, while the right gauge was labeled in absolute.

Once you understand how pressure data is displayed, you can avoid potential misdiagnosis. With those physical points addressed, we can move on to pressure sensor issues.

Pressure Sensor Issues/Diagnosis

Pressure sensors can cause driveability or transmission shifting issues. They’re an input to the ECM or TCM that rarely cause issues but you need to observe them nonetheless. A speed density vehicle will rely heavily on the MAP sensor while a MAF equipped vehicle relies on it less.

You can scope MAP sensor operation just like a TPS or APP, in the same manner covered in the last article. But you can usually observe pressure sensor issues using scan data. Of course, if you question the scan data, it’s time to break out a scope.

One of the easiest checks to perform is with the key on, engine off. Observe all the pressure sensors (MAP, BARO, Boost, etc.) and make sure they match your current actual barometric pressure. If any of them are off, continue testing the sensor in question and its associated wiring.

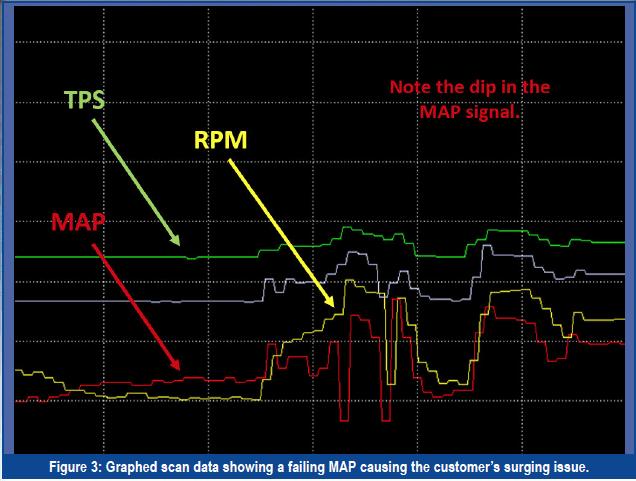

Another test would be to drive the vehicle while graphing the sensors on a scan tool. The example (figure 3) is from a Chrysler product that was experiencing intermittent surging and stalling. This vehicle had no DTCs but we could duplicate the customer’s complaint repeatedly.

You can see the TPS in green while I lightly accelerate and decelerate. Notice a visible drop in the RPM PID in yellow when the vehicle is acting up. The MAP sensor, in red, drops out to impossible values. Notice the RPM surges directly following the incorrect MAP sensor signal.

Due to the signal dropouts, we tested the electrical connection at the MAP sensor. Once we confirmed all connections and wiring were good, we replaced the MAP sensor and resolved the no-code surging issue.

Summary

Knowledge of how the vehicle and scan tool display pressure data is just as important as viewing the data itself. A misunderstanding of the displayed data can easily lead to an incorrect diagnosis and will require starting the diagnostic process again.

Engine or electrical diagnostic issues you’d like to see addressed? Let Scott know. Send him an email at [email protected] and you just may have your question covered in GEARS Magazine.

Source: https://t-tees.com

Category: WHAT