In this article, we give you the complete forklift history rundown.

With over 65 years in the business, we know a lot about the history of the forklift.

You are viewing: When Was The Forklift Invented

For example, did you know that modern-day lift trucks have a rich history dating back over 120 years?

Let’s dive in to find more such insights.

The Industrial Revolution: Manual Power

Forklifts have made a considerable impact on the material handling space.

And the seed of their invention was sown during the Industrial Revolution.

During the middle of the 19th century, industrial production was being scaled up fast.

Consequently, there was a need for faster, safer, and more efficient mechanisms for moving materials.

To meet these demands, inventors created the manually-propelled sack truck.

Consisting of a hand-crank affixed to uprights, the sack truck allowed workers to hoist heavy items like grain sacks and milk churns up to five feet high.

These sack trucks – which were continually modified – proved especially useful for industries such as chemical, gas, and agriculture.

Other types of material handling equipment used during this time included:

- Hoists with chains and winches

- Hand-powered four-wheeled trucks

- Trailers and stillages with wrought iron axles and cast-iron wheels

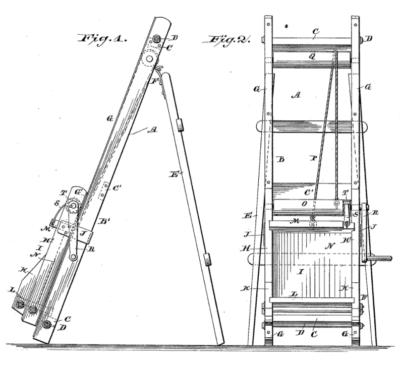

The First Patent

The year 1867 saw the first patent for a device that could both lift and transport materials.

The device was simple, consisting of an upright frame, a hoist, and a cantilever platform.

This mechanism could be attached to a cart, which would then be moved to worksites.

With this invention, workers could now move materials horizontally without having to physically pick them up first.

Twenty years later, in 1887, the next invention took place.

Called a “portable elevator,” it was an attempt to improve on the earlier 1867 model.

It consisted of an elevator mechanism that raised a platform vertically – but only a few inches.

These simple mobile elevators would lay the foundation for the modern lift truck – but not for many more years.

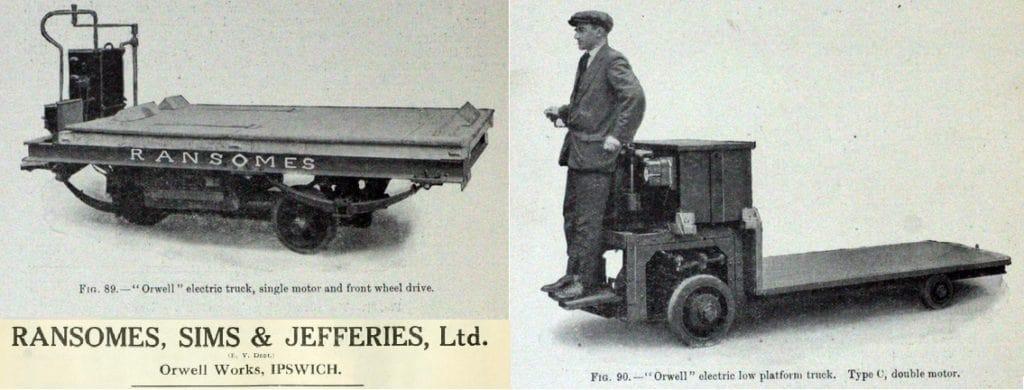

Pre-World War I: Electric Power

By the early 20th century, railroad companies had already long been using four-wheeled baggage carts.

But it wasn’t until 1906 that these carts became powered.

That was when the Pennsylvania Railroad added a battery to their cart at the Altoona Train Station.

This invention came to be known as the world’s first powered industrial truck.

And importantly, it also marked the beginning of the transition from manual to powered trucks.

Later in 1909, the first all-steel industrial truck appeared.

By combining an all-steel frame with vertical and horizontal lifting mechanisms, users were able to handle significantly heavier loads.

This invention also caused an increase in popularity and rapid deployment of these lift trucks in various industries.

Then in 1913, a new invention came into existence that would eventually change lift trucks forever: The hydraulic lift.

Unfortunately, manufacturing limitations at the time prevented them from being widely adopted until several more decades later.

With each of these innovations, the platform truck began to slowly take the shape of the modern forklift.

World War I: Labor Shortages and New Material Handling Technologies

World War I provided further impetus to new forklift technology.

For one, large government war contracts lead to the need for more labor in the factories.

But at the same time, the military draft caused an acute labor shortage.

These factors caused factories to demand more efficient means of goods and raw materials transportation that required less manual labor.

Eventually, this led to the invention of various types of material handling machines.

One such invention was the electric lift truck.

First developed by the Baker-Raulang company around 1915, it was designed as a bomb-handling crane.

While not quite a forklift yet, this development ultimately helped pave the way for the lift trucks we’re familiar with today.

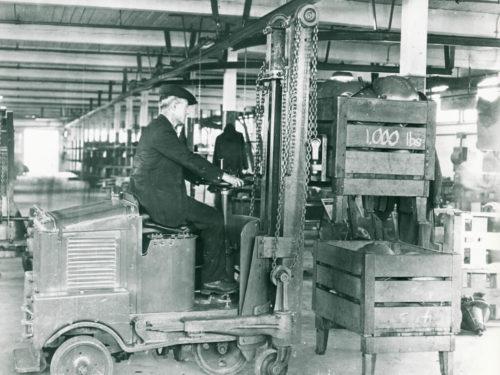

The Interwar Period: The First True Forklifts

The period between World War I and II marked the transition from platform-based industrial trucks to forklifts.

First, Eugene Clark at Clark Material Handling Company in Kentucky developed the first seated counterbalanced lift truck in 1917 called the “Tructractor.”

Although often referred to today as the first forklift, it actually did not have forks.

As Clark was dealing with heavy truck axles at the time, the Tructractor was initially developed for movement within his plant.

But soon, visitors to their plant began requesting variations of the model for their own use.

And in about two years, Clark started to export to foreign markets.

Around this time, there was also demand for a way to stack materials on top of one another.

The reason was that warehouses were eager to fit more material in less space, which allowed them to save money.

This led to Yale inventing the first electric truck with forks and a mast in 1923.

Read more : When Is Javonte Davis Next Fight

In terms of design, it resembled modern-day forklifts.

And as such, it could properly be considered the first forklift.

Who Invented the Forklift?

Unfortunately, there’s no real consensus on who invented the forklift. That said, the following could be considered the inventors of the first lift truck:

- Yale, with their 1923 electric forklift complete with forks and a mast

- Clark, with their 1924 modified Duat tractor with forks and a chain-supported mast

The truck worked by using a ratchet and pinion system instead of a tilting platform like in earlier designs.

This was a breakthrough in the sense that the mast could be elevated above the height of the truck for the first time ever.

And consequently, warehouses could take advantage of vertical space by double-stacking loads.

A year later in 1924, Clark contributed another major advancement in forklift technology.

This was the Duat tractor, which became the first internal combustion forklift.

The Standardization of Pallets

While the design of 1920s forklifts was revolutionary, there remained a significant limitation on their usefulness: There were no standard pallet sizes.

Because of this, pallets were often either too small or too large for fork trucks to handle.

By the late 1930s, engineers solved this problem by standardizing pallets.

In fact, it was only after making pallet sizes uniform that forklifts truly went mainstream.

Since forklifts were now being designed to carry pallets, the entire warehouse storage process was simplified.

Not only could pallets carry more weight, but operators could more easily stack them.

Now, this begs the question: Who invented the pallet?

The first patent was submitted by Howard T. Hallowell and approved in 1924.

Called a “lift truck platform,” Hallowell’s simple design consisted of planks attached to two support bars.

This invention allowed lift trucks to be able to pick the pallets up off the floor.

But it did not allow for stacking pallets on top of one another.

The modern-day pallet was invented by George G. Raymond, founder of the Raymond Handling Concepts Corporation.

His 1939 patent was for a “two-face pallet” design.

This concept consisted of a sturdy top face to support the load and a bottom face to rest on the load below.

And this design allowed warehouses to store even more materials in the same amount of space by double-stacking.

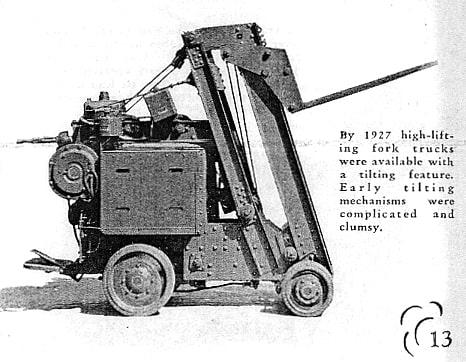

The Age of Experimentation

During subsequent years, several improvements were made to forklifts.

For example, engineers shortened wheelbases to make lift trucks more maneuverable.

To achieve this, designers move the operator compartment to the center of the truck and the battery away from the fulcrum.

This enabled a better counterbalance to maintain stability despite the shorter wheelbase.

A tilting feature, either backward or forward, was also added to the mast around this time.

This allowed operators to have better control over their loads.

Other experiments included replacing gears with hydraulics and changing from bolted joints to welded joints to increase strength.

World War II and the Post-War Years: Warehousing Changes and New Innovations

By the 1940s, forklifts looked close to what they look like today.

And they became even more popular during World War II.

With a massive increase in the need for load handling, businesses needed forklifts that could run for a full work shift.

As a result, manufacturers began to experiment with different fuel types.

Early history through the 1940s featured lift trucks with various gasoline-electric hybrid engines.

In these designs, gas powered the electric motor.

Then in 1942, Clark introduced their first battery-powered forklift, called the “Carloader.”

This lift truck was designed to be able to complete a full work shift on a single charge.

A few years later in 1947, the first diesel-powered forklifts were introduced.

And this development significantly increased the power and lifting capacity of forklifts.

Vertical Warehousing

The demand for ways to increase warehousing efficiency accelerated in the post-World War II years.

One of the key strategies for this was expanding vertically as opposed to outwardly.

By doing so, warehouses could better use available space and save money in the process.

But as slimmer aisles and higher ceilings were introduced, forklifts needed to become more narrow and easier to maneuver.

In the 1940s, the forklift was still large and cumbersome to operate.

As a result, they required a lot of space for maneuverability.

Then in 1954, a major breakthrough came when British company Lansing Bagnall developed the first narrow aisle electric reach truck.

This forklift could navigate in tight spaces while also lifting 50 feet into the air.

Read more : When Is Elvis Presleys Birthday

And ever since then, manufacturers have experimented with numerous narrow aisle forklift designs to keep up with changing warehouse footprints.

The 1960s to Today: Safety and Emissions

By the 1960s, the increased lifting height capabilities of forklifts were accompanied by safety concerns.

Falling objects from heights as much as 50 feet could seriously injure operators.

As a result, safety precautions for forklift drivers took on more importance.

One key innovation in this area was the introduction of overhead guards and load backrests.

Now, operators could be protected both from falling loads as well as tipovers.

Moving to the 1980s, manufacturers began prioritizing ergonomic designs and operator restraint systems.

These were meant to enhance operator comfort, safety, and efficiency.

Emission control also started to take shape from the 1980s onward.

By 1999, the Environmental Protection Agency (EPA) introduced the Tier system to limit engine emissions.

Other advancements in emission controls included improvements to battery design and charging.

These enabled electric lift trucks to compete with internal combustion models without emitting dangerous gases.

Load stability mechanisms were also developed in the 1990s to prevent vehicles from tipping over.

For example, Toyota implemented its System of Active Stability (SAS) and Active Mast Control in 1999.

Toyota’s System of Active Stability (SAS) uses a cylinder to stabilize the rear axle when it detects instability, helping to keep the truck upright:

Toyota’s Active Mast Function Control System limits forward and rear tilt speed when instability is detected, helping to prevent tip-overs:

These mechanisms can detect instability and limit functions to keep the lift truck stable.

The Future of Forklifts: Automation and Efficiency

If the history of forklifts has shown anything, it’s that manufacturers are constantly trying to improve designs for better safety, efficiency, and cost reduction.

Here are some of the cutting-edge developments that are in the works to do just that.

Automation

Automation is expected to play a bigger role in factories where human workers are in short supply.

For instance, the Industrial Internet of Things (IIoT), artificial intelligence (AI), and machine learning can help improve tasks such as equipment utilization.

Additionally, automated guided vehicles (AGVs) are helping reduce the reliance on human labor while also improving efficiency and safety in material handling tasks.

Predictive Maintenance

Predictive maintenance is expected to increase the reliability of lift trucks.

Servicing can be done in advance to avoid break-down, using data about expected hours of usage or from actual usage.

Part replacement or repair schedules could also soon be running on predictive analytics.

With operational data from the past being fed directly into AI, better recommendations and lower downtime could be just some of the favorable outcomes.

Electric Lift Trucks

Another significant development towards sustainability is the move towards electric lift trucks.

Powered by onboard batteries, these electric lift trucks produce no exhaust gasses and are environment friendly as a result.

The data is encouraging and shows that in the year 2010, more than 60% of all lift truck purchases were electric.

This percentage will have undoubtedly gone up as another decade has now passed since that study.

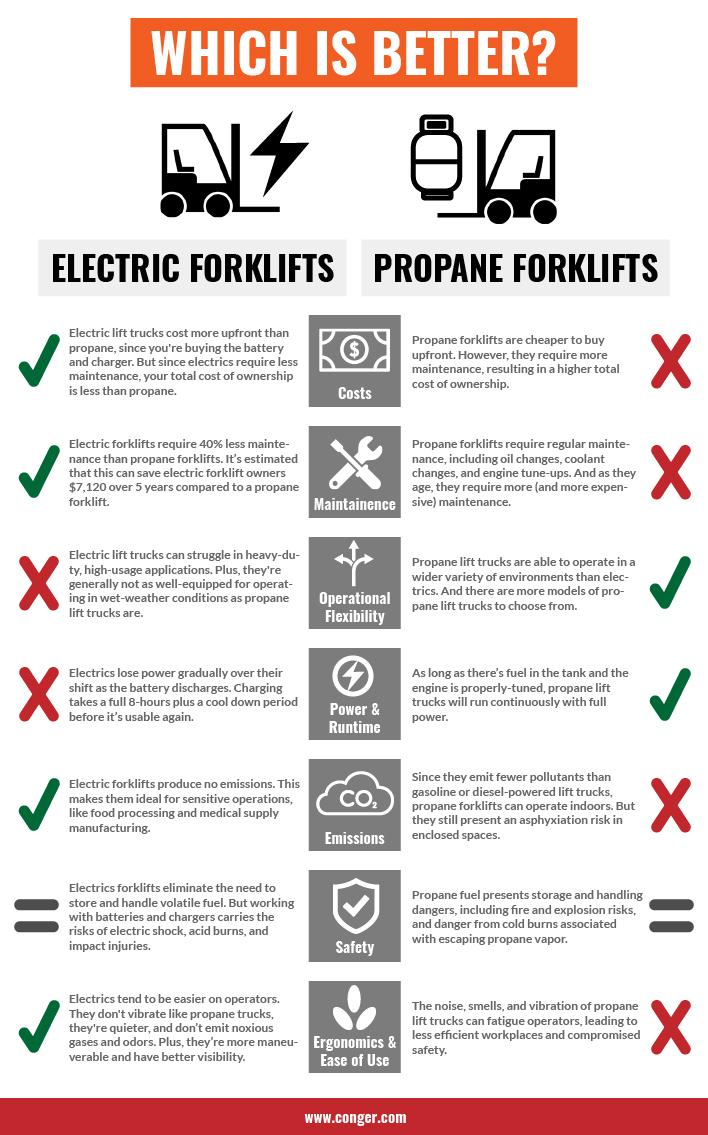

Electric forklifts are also great for cost savings as compared to propane or diesel.

Furthermore, the performance capabilities of electric lift trucks are catching up fast, with load handling capacity exceeding 15,000 pounds.

For a more detailed comparison, head over to this detailed breakdown of electric forklifts vs propane.

Lithium-Ion Batteries

Forklift efficiency is also set to increase with new fuel sources such as lithium-ion.

Lithium-ion batteries are a boon for certain industries like cold storage, which is not conducive to the life of traditional lead-acid batteries.

Also, material handling operations that run 24/7 are a good candidate for lithium-ion batteries.

Since they can be charged more quickly than lead-acid batteries, forklifts can run for longer shifts.

Other benefits over lead-acid batteries include:

- Lower maintenance costs

- Higher fleet availability

- Longer lifespans

- More energy savings

- Faster charging

- No harmful fumes

Large-scale penetration of lithium-ion batteries is expected as the technology matures.

And this will result in lower prices along with better scaling and distribution.

Fuel Cell Forklifts

Another popular, emerging power source for forklift is the fuel cell.

In a fuel cell, electricity is produced by the reaction between hydrogen and oxygen.

An eco-friendly alternative, these fuel cells only produce water as a by-product.

And just like lithium-ion batteries, fuel cell technology has low noise levels.

They can also be charged within minutes, which makes them a good fit for warehouses with high-volume applications.

All these changes are expected to provide numerous options for managers when planning their fleets and acquiring new and used forklifts.

Conclusion

That concludes the complete history of forklifts.

Source: https://t-tees.com

Category: WHEN