OVERHEAD DOORS AND SECURITY BARS: FORCIBLE ENTRY CHALLENGES

The term forcible entry is defined simply as “the act of entering by using force against opposition or resistance.” However, the practical application of techniques that allow fire service personnel to enter restricted areas in a timely manner often are far from simple. As security techniques and building construction methods— for both commercial and residential structures —change in concert with the trend to protect personal property, the fire service is presented with new challenges.

You are viewing: Which Method Would Be Used To Force An Overhead Door

Ideally, entry should be as easy as turning a doorknob or opening a gate, but this normally is not the case. When encountering unique or new security problems, fire personnel must combine innovation and imagination with good judgment, common sense, and experience to produce a successful operation.

Two common devices designed to restrict entry are overhead dtxirs and security bars. Overhead doors are found primarily in commercial-industrial occupancies, while security bars are used on numerous types of occupancies to secure both doors and windows. Let’s look at several forcible entry considerations for overhead doors and security bars.

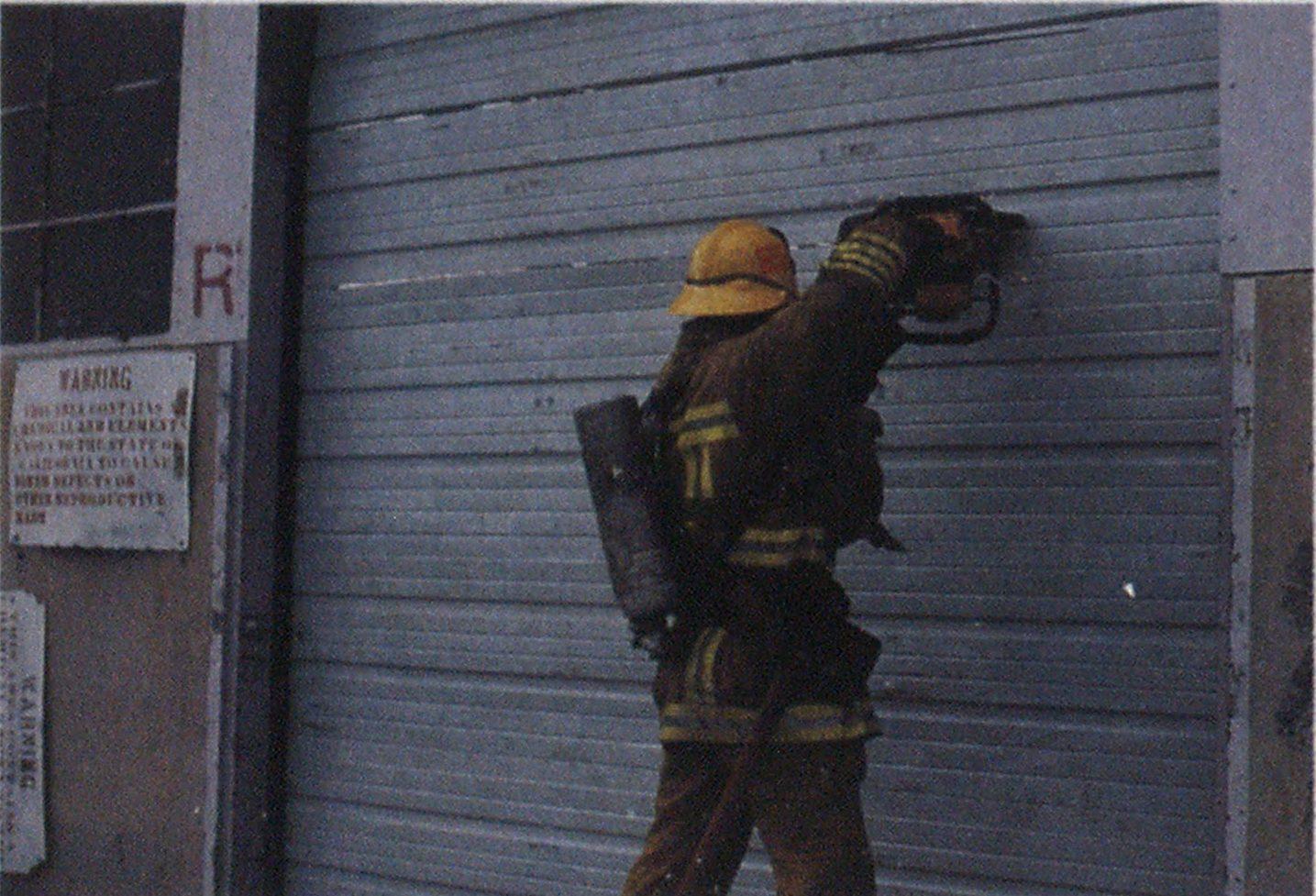

OVERHEAD DOORS

Overhead doors are used to cover various types of openings, particularly loading dock and large garage-type doors in commercial structures. These types of doors may have internal and/or external locking mechanisms, consisting of lock cylinders, padlocks, slide holts, or manual-mechanical-operated mechanisms. If forcible entry operations are applied unsuccessfully to exterior or interior locking mechanisms, you must force entry through the overhead door. The triangle, teepee, or inverted “V” cut is a common forcible entry technique for these doors. This method will provide entry, but it has the following drawbacks:

- It requires at least two large cuts.

- It normally results in an opening that is narrow at the top and wide at the bottom. This type of opening does not offer easy access and egress of personnel, particularly the emergency egress of multiple personnel.

- Unless the cut portion of the door is removed, personnel will walk over loose metal in the doorway opening.

- Once a hoseline is advanced through this type of opening, you cannot raise the door unless you remove the bottom portion of it.

- Alternative methods that may require less effort and time to force entry through overhead doors are as follows:

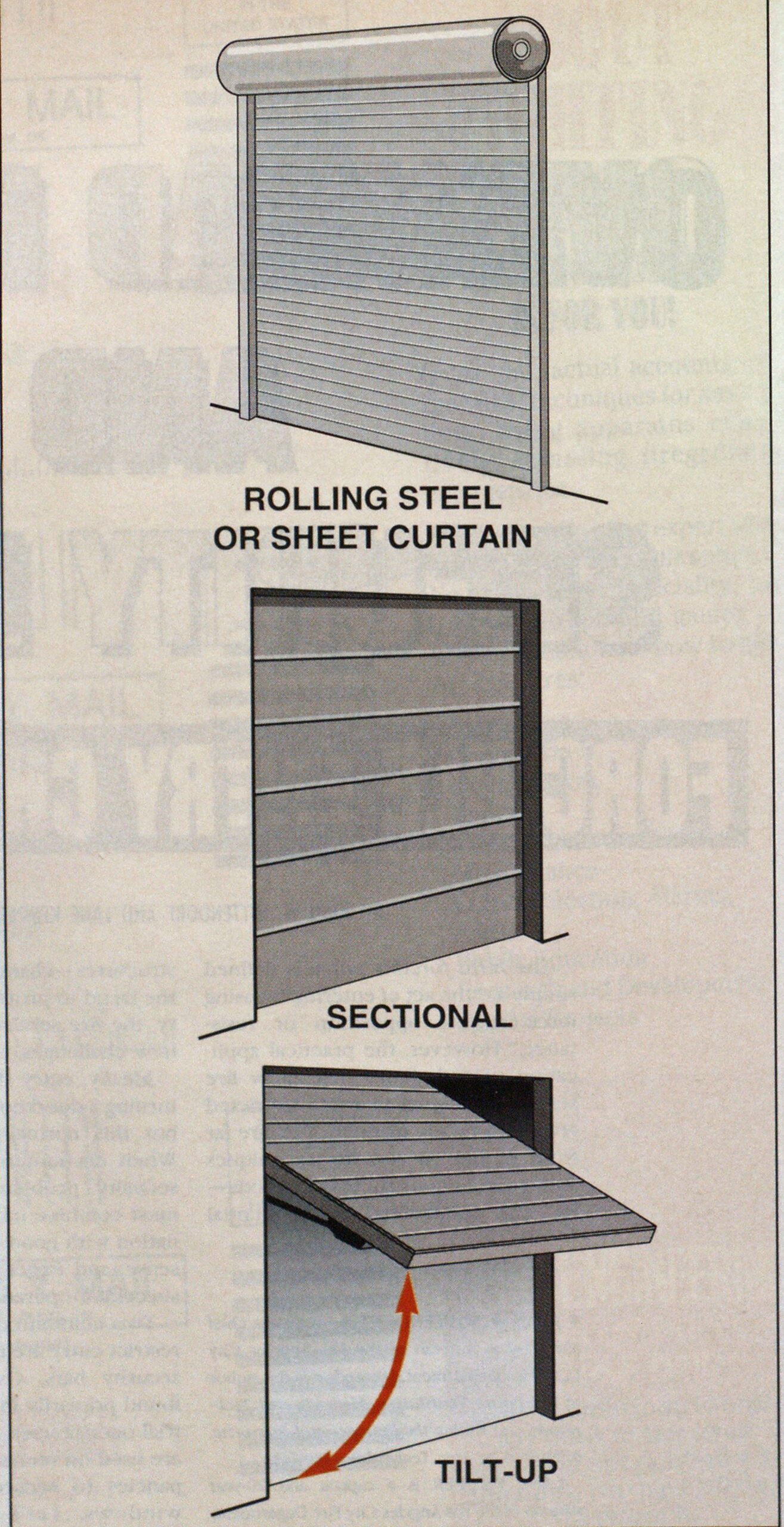

- Rolling steel. These doors, constructed of interlocking steel slats, open and close by rolling around a spring-loaded, manually or mechanically operated drum at the top of the door.

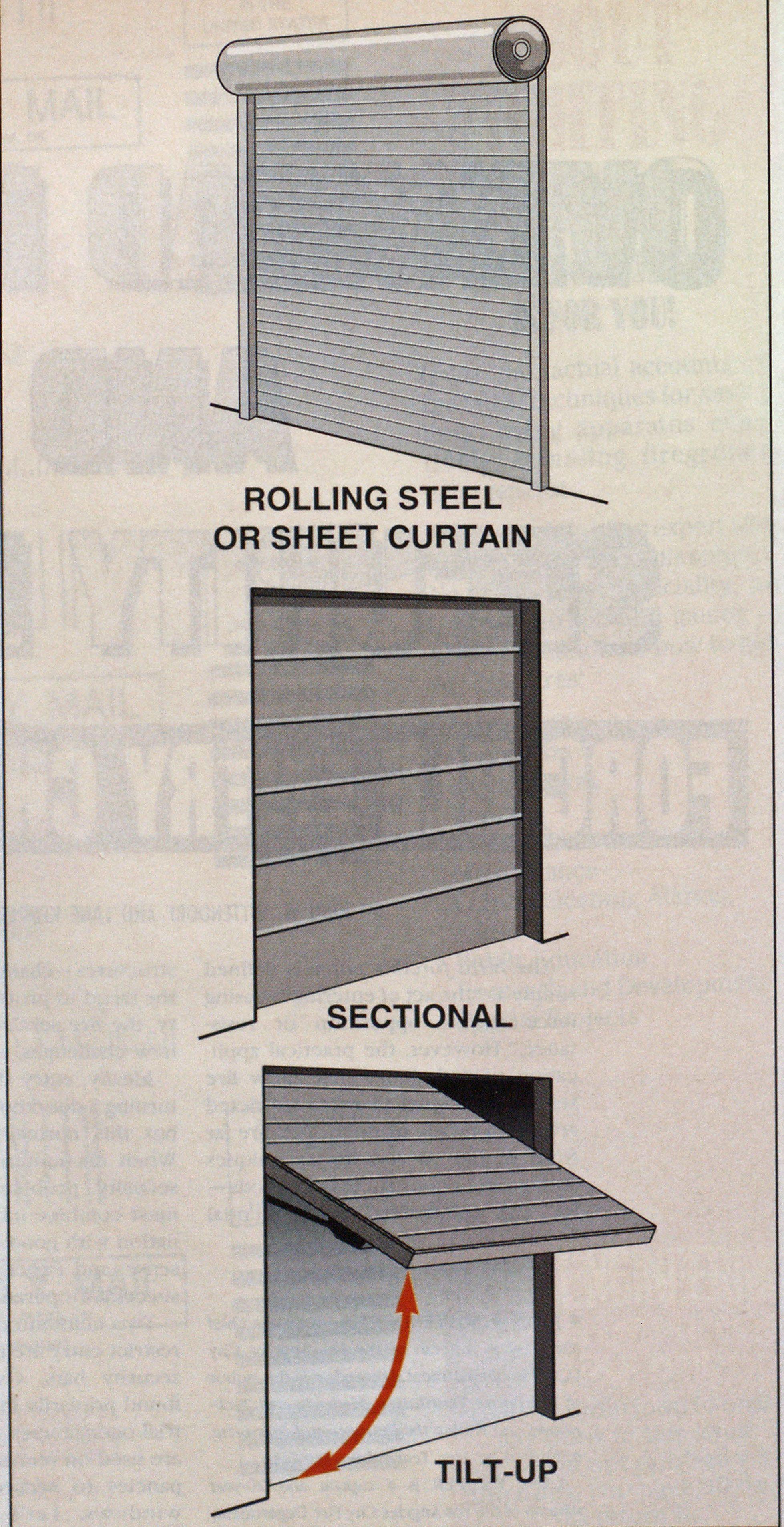

- Using a rotary saw, make a cut down the center of the door, starting about head height and continuing down to the steel channel at the bottom of the door. If slats have been damaged (bent) from being struck by a vehicle (e g., a forklift), they will not pull free. Initiating the vertical cut about head height will allow you to pull some slats above any damaged slats and most locking mechanisms (padlocks, slide bolts, and so forth).

- Make a small angular cut at the bottom of the vertical cut to create a small opening. Place a rotary saw into this opening and cut through the steel channel at the bottom of the door.

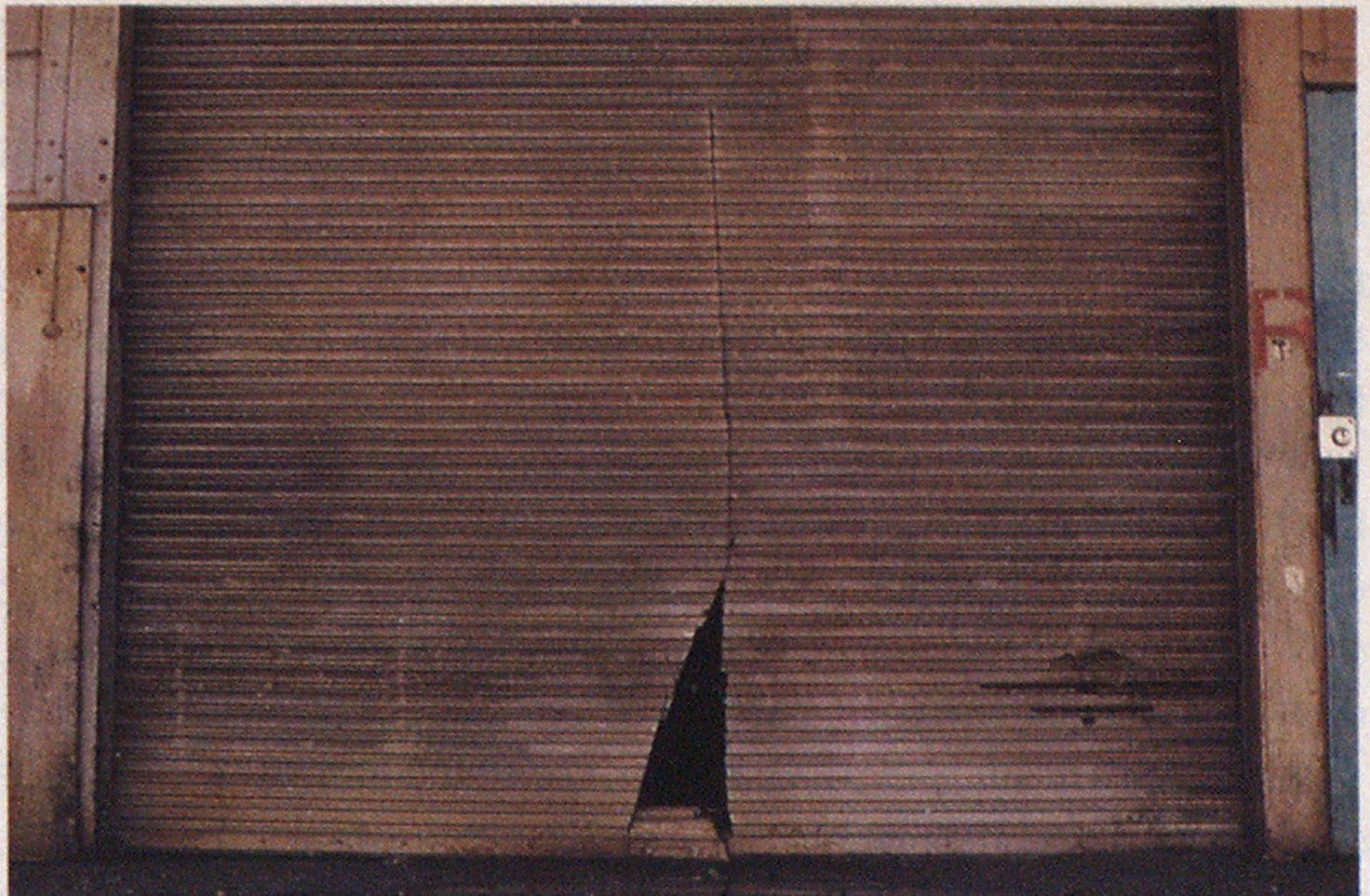

- Use channel locks, vise grips, or similar tools to pull a slat from either the left or right side of the vertical cut. After you have pulled the slat free, all slats below the pulled slat will fall to the ground, where they easily can be pushed away from the door opening.

- Pull an opposing slat to release all slats on the opposite side, and remove all cut slats from the door opening.

- Most rolling steel doors are constructed with a guide on every other slat. Slats without guides are easily pulled free. However, some doors have guides on every slat. Slats with guides cannot be pulled free. If a slat cannot be pulled free, use a rotary saw to cut through several slats on each side of the door (and next to the door frame), making it possible to pull slats free and release all lower slats.

(Photos by author.)

Read more : Which Pharmacokinetic Phase Is Affected By A Compromised Renal System

Once the appropriate slats have been pulled, opening the entire lower portion of the door, the remaining upper portion of the door, if springloaded, will raise. If you can manually or mechanically operate the door, you will be able to completely open it. If the door is inoperable, this method still will provide a significantly larger opening (with less cutting and in less time) than the opening that is provided by a teepee cut.

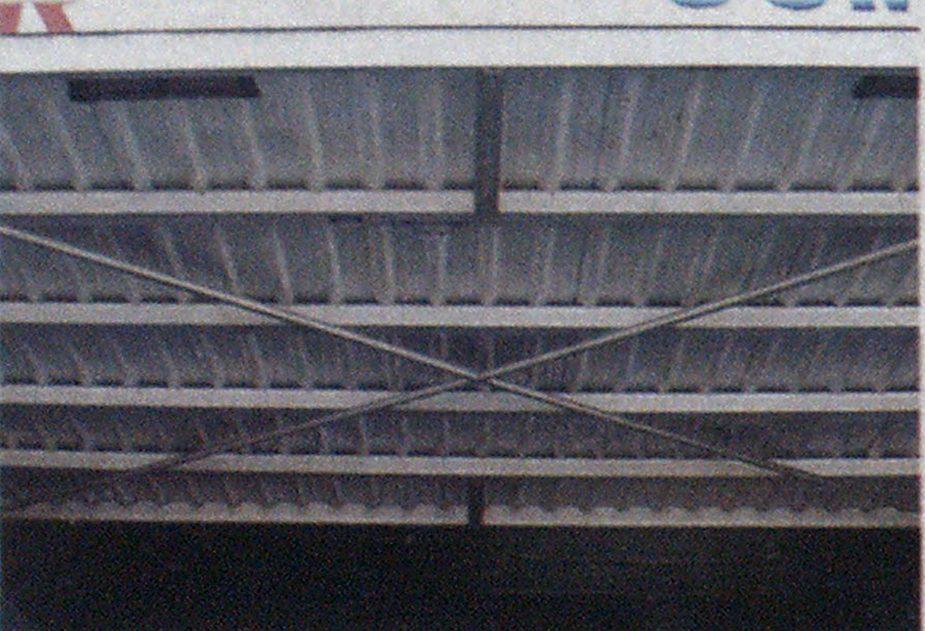

Sheet curtain doors. Sheet curtain doors look similar to rolling steel doors, but they are constructed of thin steel panels instead of steel interlocking slats. The panels are joined together to form a solid-piece door. This continuous panel opens and closes by rolling around a springloaded, manually or mechanically operated drum at the top of the door. This type of door can be forced by using the procedure used for sectional doors.

Sectional doors. These are comprised of steel or wood sections that are hinged to each other and open and close by either rolling around a drum at the top of the door or traveling vertically (in tracks mounted in the door jamb) or horizontally (in tracks mounted in the ceiling).

- Make a horizontal cut the entire width of the door at approximately shoulder height. If necessary, balance the rotary saw on your shoulder to support the weight of the saw and simplify the cutting operation. Use a chain saw or rotary saw with a carbide-tipped wood blade on a wood sectional door.

- Do not cut near the joint between two sections; to do so necessitates cutting steel hinges (between the sections on the back of the door), unnecessarily slowing the cutting operation.

- Next to the left or right side of the door, make a vertical cut from just below the horizontal cut down to the steel channel at the bottom of the door. Do not start this cut by joining the vertical cut with the horizontal cut —doing so w ill allow the cut panel to open, and heat, smoke, or the panel will hinder the saw operator.

- Make a small diagonal cut at the bottom of the vertical cut to create a small opening. Place a rotary saw’ into this opening and cut through the steel channel at the bottom of the door, litis operation is not necessary for wood sectional doors.

- Join the vertical and horizontal cuts, allowing the cut panel to be swung outward and away from the opening, creating a large opening.

- If necessary, the saw operator easily can cut any remaining metal rollers (that were used as a hinge point and still are securing the door to the door jamb). The cut portion of door can be completely removed from the door opening. If the door is spring-loaded, the remaining part of the door (above the cut ) w ill retract upward. If the door is manually or mechanically operated, you should be able to fully open it.

Tilt-up doors. Tilt-up doors are single-piece doors constructed of thin steel and hinged at the middle to swing up or down (similar to a garage door). This door can be forced using the same operation as that used for sectional doors. When cutting this door with a rotary’ saw, it is important to use a large saw and bury the blade as deep as possible to cut the metal braces on the back of the door.

If the springs or hinges on these types of doors (or other garage-type doors) have been exposed to heat or fire, they may be weakened to the point of being incapable of supporting a door. In such a case, you should support the open tilt-up door with a pike pole or use vise grips to lock a hinge.

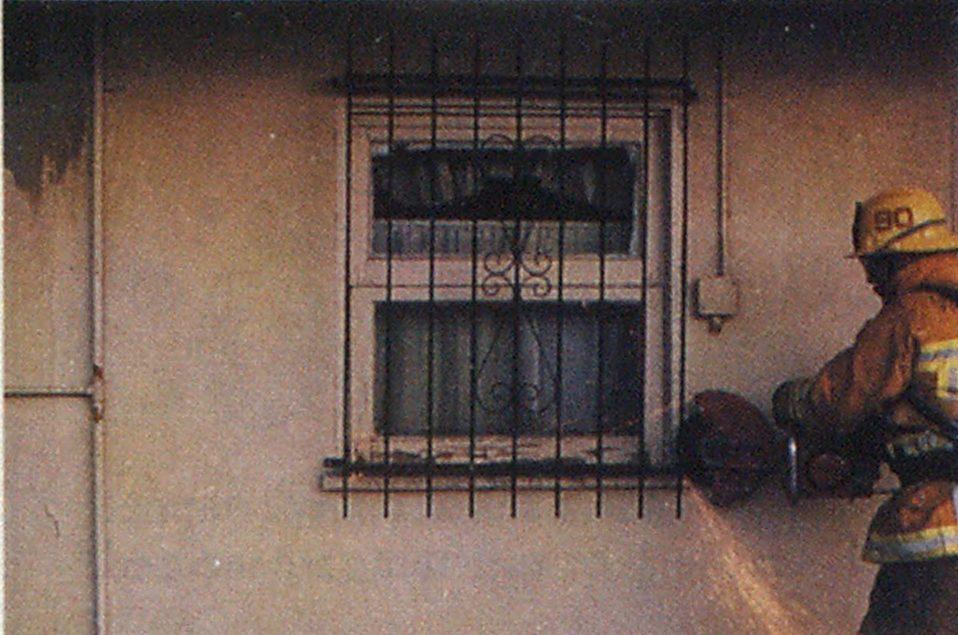

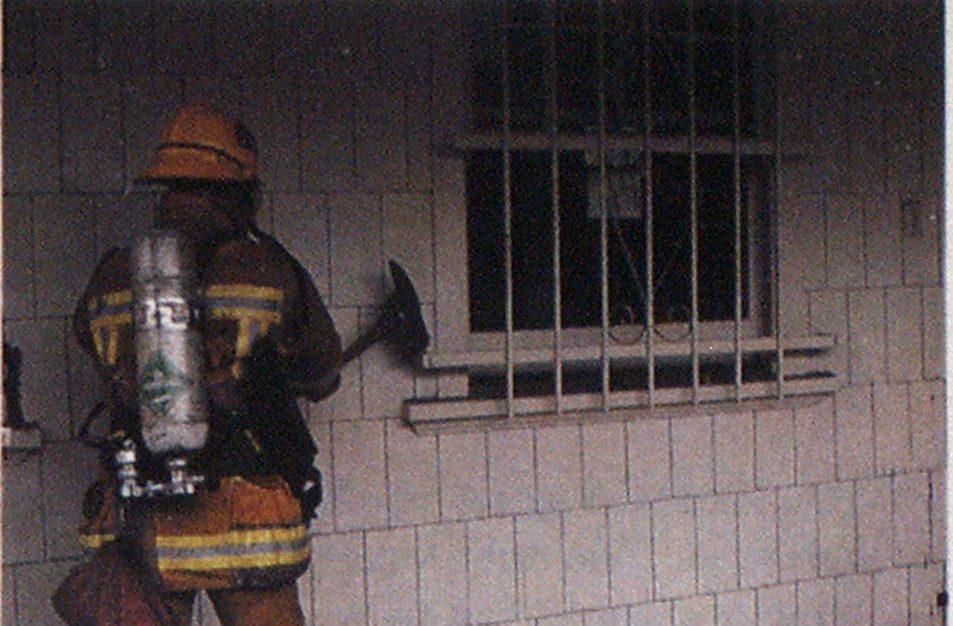

SECURITY BARS

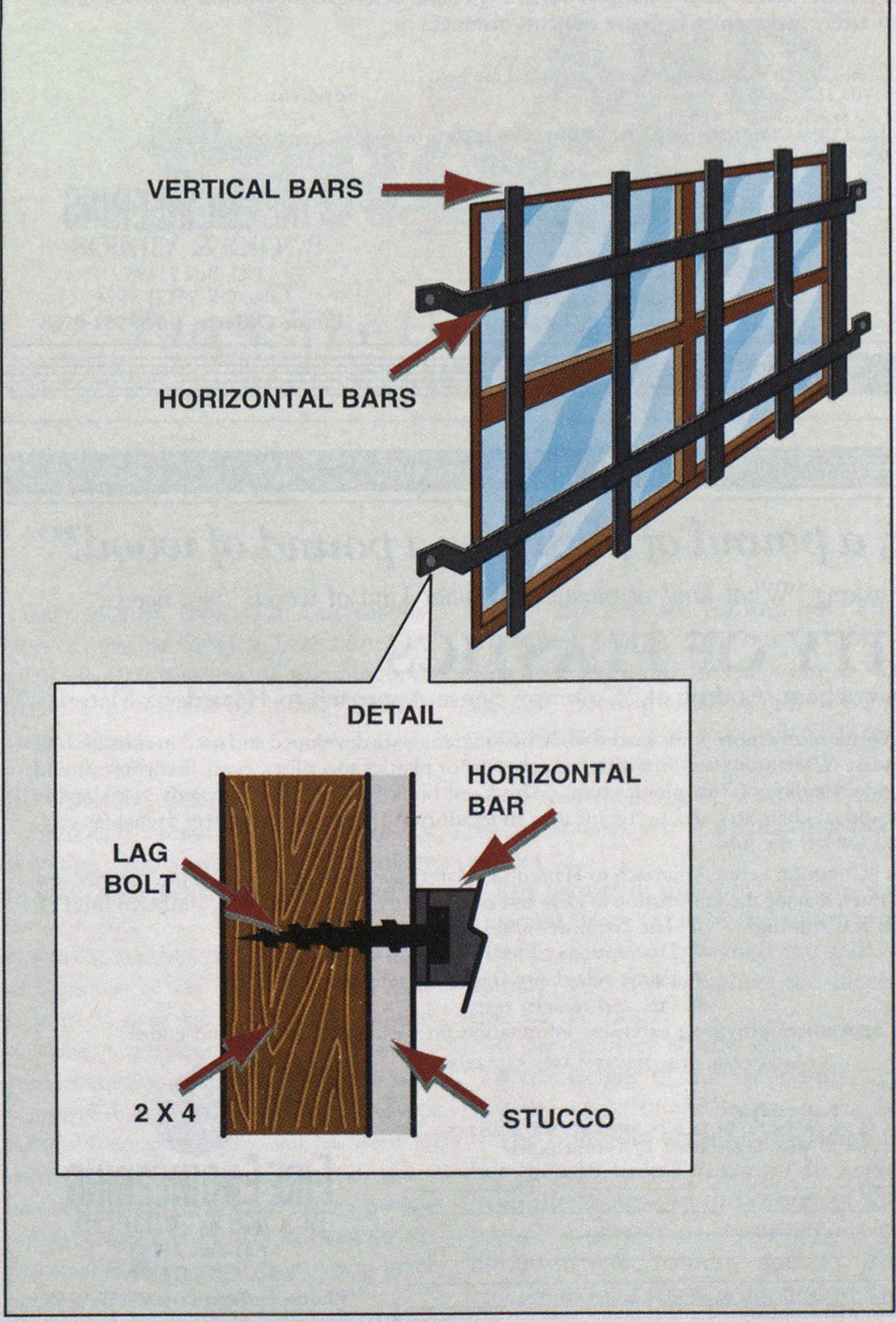

Security bars often are used on windows (and doors) in residential and commercial occupancies to provide protection against vandalism and theft. Although security bars enhance security, they also may present a serious problem, since they restrict egress from a structure. During a structure fire, the presence of security bars may prevent occupants from using windows as a means of escape and fire suppression personnel from using windows as an emergency means of egress. Security bars normally are constructed and mounted on structures as follows:

- Construction.

— Horizontal bars.

— Vertical bars.

Read more : Which Tech Career Is Right For Me Quiz

— Lag bolts.

- Mounting.

— Mounted outside an exterior wall and over w indows on residential or commercial structures. Attached to structure by lag bolts.

— Mounted in a wall and over windows on commercial structures. Attached to structure by lag bolts or by placing bar ends in masonry walls.

An outline of methods for removing different types of security bars from windows follows.

Wood-frame structures.

- Use a rotary saw to cut the horizontal bars (top and bottom, on either the left or right side) near the anchor points to the structure and bend the bar assembly away from the window. It also is possible to cut the bottom horizontal bar near both left and right anchor points and bend the bar assembly upward and away from the window. However, this method is not recommended due to the possibility that the bar assembly will fall downward over the window.

- Cutting vertical or horizontal bars near all anchor points will allow you to remove the entire bar assembly from a structure (time and conditions permitting). However, when one person performs this operation, the bar assembly will fall outward when the last anchor point is cut. Therefore, the saw operator must stand to the side of the bar assembly while cutting the last anchor point.

- Security bars that can be opened from the inside of a structure (they are identified by exterior hinges on the bars) are most easily removed by cutting the bracket, which connects the bar assembly to the interior opening mechanism, with a rotary saw and then simply opening the bar assembly away from the window.

- Use a sledgehammer to strike the horizontal bars near their anchor points. When the lags have been pulled from a structure, bend the bar assembly away from the structure. However, it is difficult for personnel to consistently strike the upper horizontal bar near the anchor point with a sledgehammer to remove the lag bolt.

An alternate method of removing security bars with a rotary saw or sledgehammer is as follows:

Use a pickhead or flathead axe to strike the horizontal bars near their anchor points to a structure. This method is very effective for driving the lag bolts out of a structure and, in most cases, will require less time than using a rotary’ saw or sledgehammer. When the lags have been pulled from a structure, you can bend the bar assembly away from the window.

Masonry construction Security bars that are mounted outside an exterior wall and over a window are easily removed using the following method:

- Cut the ends (left or right) of the horizontal bars with a rotary saw and bend the bar assembly away from the window. When you bend the bar assembly away from the window, the remaining lags often will pull out, releasing the entire bar assembly from the structure.

- Strike the ends of the horizontal bars, near the anchor points, with an axe or sledgehammer. This method is very effective, since the lags arcscrewed into lead anchors This assembly is held together by compression against the masonry construction. A sharp blow with an axe or sledgehammer should easily break the masonry construction around a lag and lead anchor and force the lag and anchor to pull out.

- Place a large crowbar between the anchor points and masonry wall and pry outward.

Security bars mounted in a wall and over a window. Security bars mounted into a masonry wall may be more secure than security bars mounted outside a wall and may provide less opportunity to access using striking and pry ing tools. If necessary’, you can remove bar assemblies that offer minimal access by cutting the ends of the horizontal and/or vertical bars imbedded in the wall with a rotary saw and removing the bar assembly from the wall.

Source: https://t-tees.com

Category: WHICH