Rope is an increasingly common product in both work and daily life. Therefore, the materials used to make ropes are receiving growing attention and emphasis to create quality products that meet diverse human needs and purposes. Let’s explore the top 5 most common rope-making materials in the article below:

- Polypropylene (PP) Resin

- Polyethylene (PE) Resin

- Polyester (PET) Resin

- Nylon

- Steel Cable

1. Polypropylene (PP) Resin Virgin PP (polypropylene) resin is a type of polymer. PP resin is the most commonly used material for rope production on the market today. Moreover, PP resin is a versatile material widely used in various fields such as:

-

Everyday household items: water scoops, hairbrushes, basins, plastic trash cans, clothing hooks, etc.

-

Industrial applications: plastic pallets, packaging materials, etc.

Key characteristics of virgin PP resin:

-

Relatively light density, flexibility, and high surface finish.

-

Aging occurs quickly when exposed to prolonged outdoor conditions.

-

Brittle, prone to breaking into pieces at low temperatures.

-

Good electrical insulation.

-

Melting temperature of virgin PP resin: 165-200°C.

-

The specific gravity of virgin PP resin: 0.92g/cm³.

-

Destruction temperature of PP resin: 280°C.

-

Appropriate mold temperature for PP resin molding: 55-65°C.

-

Shrinkage of virgin PP resin: 1.0〜2.5%.

-

Strength against force: 30-40 N/mm².

-

Elongation at break: 250-700%.

-

Impact resistance: 3.28-5.9 kJ/m².

-

Colorless, odorless, tasteless, non-toxic, and emits a pale green flame when burned, with a rubber-like odor.

Products made from virgin PP resin are generally lightweight and highly durable. They exhibit resistance to O2, oils, grease, and water vapor. Overall, PP resin is an excellent material for the production of various types of ropes used in fisheries, longline fishing, maritime activities, agricultural applications, aquaculture, etc. However, it is important to note that when using ropes made from PP resin, proper storage is crucial to ensure a longer lifespan. Limit exposure to direct sunlight, as prolonged exposure can degrade the quality of the rope.

Pic1: PP Resin

2. Polyethylene (PE) Resin Virgin PE (polyethylene) resin is a type of polymer. PE resin is the second most commonly used material in rope production after PP resin in the market. The advantage of PE resin is that it is the safest material among virgin plastics in the market. The reason PE resin is not as common as PP resin is that the characteristics of PE resin make it more suitable for packaging, so in the plastic packaging industry, PE resin is the leading material. However, ropes made from PE resin are also very popular because they serve many other human needs. Key characteristics of PE resin:

-

Transparent, slightly cloudy, glossy, and flexible surface

-

High melting point: ~120°C

-

Non-conductive and non-heat-conductive

-

Excellent waterproof and vapor-proof properties

-

Poor resistance to O2, CO2, N2, and low resistance to oils and greases

-

Susceptible to swelling and damage when in contact with aromatic oils or cleaning agents

Classification of PE plastic: PE plastic is divided into 8 types depending on the degree of branching, molecular weight, and density.

-

VLDPE (Very Low-Density Polyethylene) has a very low density of 0.880 – 0.915 g/cm³, with a straight chain and short branches. It is a shape-memory material, soft, and has good flexibility.

-

LDPE (Low-Density Polyethylene) has a low density of 0.910 – 0.925 g/cm³.

-

LLDPE (Linear Low-Density Polyethylene) has a low density with a straight chain of 0.915 – 0.925 g/cm³.

-

MDPE (Medium-Density Polyethylene) has an average density of 0.926 – 0.940 g/cm³.

-

HDPE (High-Density Polyethylene) has a high density of 0.941 – 0.965 g/cm³.

-

UHMWPE (Ultra-High-Molecular-Weight Polyethylene) has an extremely high molecular weight ranging from 3.1 to 5.67 million with a density of 0.935 – 0.930 g/cm³. This type of PE is often rigid.

-

PEX or XLPE (Cross-Linked Polyethylene) has a cross-linked structure.

-

HDXLPE has high density and cross-linking, synthesized by adding PE oxide.

Applications of PE plastic: Although all belong to the PE family, each type of PE plastic has different applications. For example, VLDPE is often used to produce gloves, stretch films, packaging wraps, or used as a component in the transformation process of other plastics. UHMWPE is used for making fibers and bulletproof panel lining due to its rigid physical properties. Meanwhile, HDXLPE is the main material for producing plastic films, pipes, wires, and electrical cables. In addition, PE resin in general is used to manufacture bags or plastic containers of various sizes, ranging from 1 to 20 liters. PE is also used to produce various types of bottle caps and devices in the chemical industry. In the field of rope, HDXLPE resin specifically can produce various types of ropes such as straw column ropes, banana column ropes, vine climbing ropes, and greenhouse ropes.

Pic2: PE Resin

3. Polyester (PET) Resin Polyester resin, or poly, is an abbreviation for Polyethylene Terephthalate (PET). Polyester is the general term for fabrics made from synthetic polyester fibers. Polyester resin is a material synthesized with ethylene as its main chemical component. This chemical compound is researched from the origins of coal and petroleum. Nowadays, polyester fibers are created by conducting a chemical reaction between acid and alcohol. In this reaction, when molecules come together and bond randomly, they form larger molecules with a consistent structure and properties. Characteristic features of PET plastic:

-

Excellent wrinkle resistance

-

Not permeable to water

-

Resistant to moisture and mold

-

Difficult to get dirty

-

Easy to clean

-

Diverse color options

-

Good flame resistance

Applications of PET plastic: Polyester resin (PET) is used to manufacture various products in daily life, including:

-

Furniture

-

Fashion items

-

Lifestyle accessories

-

Molded plastics such as composite electrical cabinets, fishing boats, composite ships, fishery inspection vessels, composite planters, composite swimming pools, and pipes for gas transportation.

In the field of rope production, PET is utilized to create “High-End” products. Its glossy appearance, vibrant colors, and versatility make it suitable for manufacturing decorative ropes, yacht ropes, and sailboat ropes.

Pic3: PET Resin

4. Nylon Nylon plastic is a type of synthetic polymer containing repeated amide bonds along its main chain. Nylon is commonly produced in the form of plastic pellets or small beads, and it finds numerous applications in various fields due to its unique mechanical and chemical properties. Key characteristics of nylon plastic:

-

Sturdy, durable, and resistant to abrasion

-

Rigid, somewhat flexible, with the ability to resist impact and high abrasion

-

High melting point

-

Hygroscopic nature (tendency to absorb moisture)

-

Colorless, odorless, and tasteless

Applications of nylon plastic:

-

3D printing material

-

Everyday items: hairbrushes, toothbrushes, clothing hooks, mesh bags, plastic fruit packaging bags, plastic bags for storing items, etc.

-

Fiber production

-

Tubes and pipes: suction tubes, plastic water pipes, air and oil conduits

-

Mechanical accessories: bearings, gears, pulleys

-

Tires

Protective sheaths for metal layers in electrical wires Regarding its use in rope production, nylon plastic is not as commonly employed as the three popular polymer types: PP, PE, and PET. Nevertheless, there are still various types of ropes made from nylon that cater to specific needs due to their high strength, elasticity, heat resistance, resistance to abrasion, and protection against chemical impacts. It can be used for applications such as fishing lines, nylon nets, and bridge climbing ropes.

Pic4: Nylon Resin

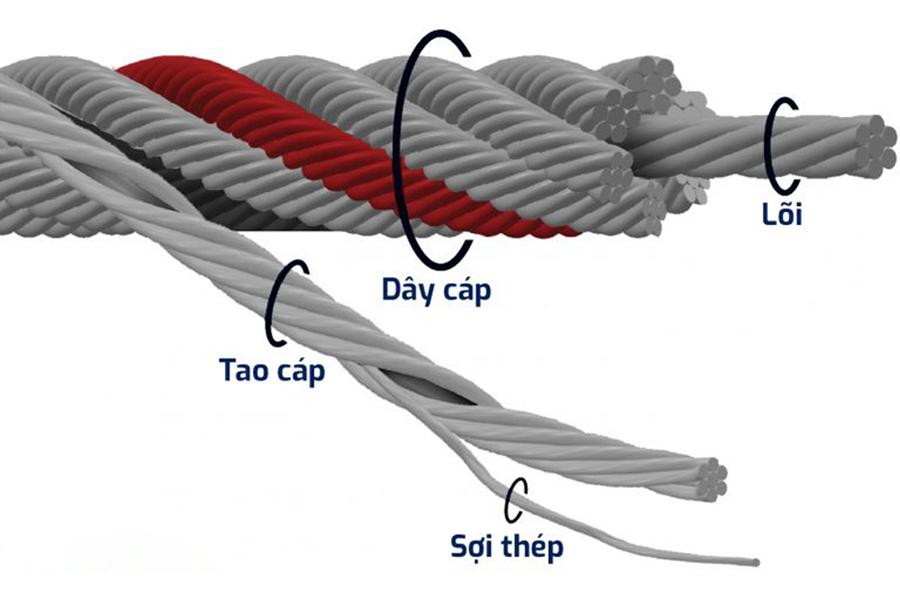

5. Steel Cable Steel cable is a special type that doesn’t fall into the category of ropes, but due to its widespread use and applications, it’s essential to know more about this steel material as well as the type of steel cable. A steel cable is a metallic strand (formerly iron, but predominantly steel nowadays) composed of three main components: the cable core, cable strand, and cable bundle. The cable strand is made up of numerous steel wires twisted around a central core wire. The twisting structure is similar to that of a rope. These cable strands are then twisted/braided together to form a cable bundle, with the number of cable strands in each bundle varying based on usage needs (typically 6 cable strands, each with 36 or 37 wires). Key characteristics of steel cable:

-

Made of steel, ensuring strength.

-

High tensile strength and elasticity.

-

Excellent resistance to corrosion and heat.

-

Can withstand heavy loads and high pressure.

Pic5: the structure of steel cable

In summary, the five most common types of materials widely used in everyday life are:

- PP Plastic Pellets

- PE Plastic Pellets

- PET Plastic Pellets

- Nylon Plastic

- Steel for Steel Cable

Depending on the intended use, each material produces different types of ropes suitable for specific purposes. For customers interested in purchasing ropes made from PP, PE, and PET plastic pellets, meeting European standards and international tensile strength requirements, please contact Siam Brothers Vietnam through the following communication channels:

Siam Brothers Vietnam Joint Stock Company

Tel: (+84) 28 38 912 889

Read more : Which Wich Application

Hotline: 1800 6129

Website: siambrothersvn.com

Fanpage: facebook.com/siambrothersvn

Email: [email protected]

Youtube: youtube.com/@siambrothersvietnam1728

Twitter: twitter.com/sbvnjsc

OA Zalo: zalo.me/1402339229697925373

App SBVN ID:

- CHPlay: https://bit.ly/SBVNID-Android

- Appstore: https://bit.ly/SBVNID-iOS

Source: https://t-tees.com

Category: WHICH