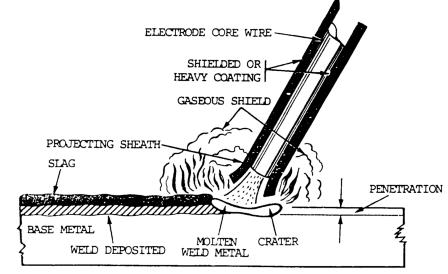

Welding rods, also known as electrodes, are the materials that are melted and infused during processes such as stick welding. To utilize a rod, you must first attach it to your welding equipment, creating an electric arc between the base metal and the welding rod. Because the electric arc is so intense, it quickly melts the metal, fusing the pieces.

Welding requires careful rod selection. During a welding process, the rod deposits filler metal in the weld. Because consumable materials are entirely absorbed throughout the process, selecting a material chemically compatible with the metals being welded together is critical. Steel, such as low alloy or nickel steel, is one of the most commonly used materials for consumable electrodes.

You are viewing: Which Welding Rod To Use

Read more : Which Of The Following Is True Of Type I Diabetes

Rods for stick welding have a shielding or heavy coating that contains flux. When the flux burns, it releases gasses to eliminate oxygen from the molten pool. The type and degree of coating or flux on the electrodes can also be specified, ranging from no flux coating at all to extensively coated varieties. Rods with no coating are used in TIG welding processes with equipment that introduces inert gases at the point of the weld.

Types of Stick Welding Rods

- 6010 – One of the most widely used choices, as it is suited for high-power density welds. Welding rods of this type are commonly used for pipes, shipyard welding, steel storage tanks, water towers, and other applications using thick metals. The 6010 welding rods, however, can only be utilized with DC welding machines.

- 6011 – This produces an easily controlled arc with deep penetration and high-quality weld metal. These electrodes are suitable for new and clean materials, thinner materials, and broader root openings. They are famous for repairing cars, engines, agricultural equipment, and other greasy, rusty, and dirty items. These welding rods can be used with either AC or DC welding machines.

- 6013 – These electrodes can be used in any position with AC or DC (straight or reverse polarity). 6013 electrodes are comparable to 6011 electrodes in tensile strength, welding conditions, and current types. These types of welding rods are used in new construction and fabrication works.

- 7018 – This welding rod is considered one of the most versatile welding rods available. Because the 7018 welding rod is suitable for both AC and DC welders, it is employed in factories, bridges, power plants, and a variety of other heavy-duty applications.

Source: https://t-tees.com

Category: WHICH