Have you tried placing a shipping order to restock your inventory in the last six months? If you did, you probably had a heart attack when you saw how much it would cost.

International shipping rates are at all-time highs. Along the China-EU shipping lane, TIME reports: “Transporting a 40-foot steel container of cargo by sea from Shanghai to Rotterdam now costs a record $10,522, a whopping 547% higher than the seasonal average over the last five years.” Between Asia and North America, Bloomberg reports that “contract rates…are coming in around $2,500 to $3,000 for a 40-foot container—25% to 50% higher than a year ago…” And between China and the UK, the cost of shipping has gone up by over 350% in the past year.

You are viewing: Why Is International Shipping So Expensive

The question remains: why is shipping so expensive in 2021? The primary reason for the sudden spike in the price of shipping is the world’s ongoing nemesis: COVID-19. The pandemic affected global supply chains in 2020, and shipping prices reflect that. With prices estimated to remain at these levels until 2023, both ecommerce businesses and other small businesses should consider diversifying their fulfillment options to reduce shipping costs in the near term.

In this article, we’ll break down the key factors that led to the current rise in shipping prices and ways in which businesses can mitigate their shipping costs.

Jump to the section of the article that you find most interesting:

- There’s a Global Shipping Container Shortage

- The Suez Canal Accident Had a Significant Impact

- Major Ports in China Are Facing New COVID Threats—Leading to Further Delays

- How Can Companies Mitigate Their Shipping Costs?

There’s a Global Shipping Container Shortage

After the world went into global lockdown in response to COVID-19, China reopened its economy faster than the US and Europe. However, the shipping containers China needed to ship manufactured goods were stuck in those two regions. This led to a shipping container shortage for China.

In January, Mark Yeager of Redwood Logistics commented: “There are about 180 million containers worldwide, but ‘they’re in the wrong place.’”

According to Triton International, orders for new containers were canceled in the first half of last year due to the pandemic, and estimates in April show that Chinese shipping container manufacturers have been producing only 2-3 weeks’ worth of supply in the market as they try to catch up.

Every spot on an available container in China has a massive price surcharge to reflect the heightened demand in the market. Prices for new containers are now “$3,500 per cost equivalent unit (CEU, a measure of the value of a container as a multiple of a 20-foot dry cargo unit) versus $1,800 per CEU in early 2020 and $2,500 per CEU in late 2020.”

The Suez Canal Accident Had a Significant Impact

Read more : Why Does My Cat Bite Me Gently While Purring

In March 2021, the shipping vessel Ever Given got stuck in the Suez Canal and blocked the entire waterway for a week. This accident caused shipping charges to shoot up even more.

12% of the world’s trade goes through the Canal, and the incident roughly cost $2.2 billion to $3.9 billion in international trade because of the delays that were caused by it.

Although the Canal isn’t blocked anymore, the blockage caused delays for ships that were on their way to their destinations. Ports are already dealing with delays in berthing and dispatching cargo ships—further delays from incidents like these put more pressure on freight rates.

Major Ports in China Are Facing New COVID Threats—Leading to Further Delays

If a shipping container shortage and a freak shipping accident weren’t enough, COVID-19 case spikes continue to be a threat around the world, including in the USA and Japan.

This latest uptick has been linked to the Delta variant, which originated in India and was detected in early June in Guangdong province in China, which is a hub for 24% of China’s total exports.

Over 100 positive COVID-19 cases have been reported in Guangdong cities, like Guangzhou and Dongguan, and the Chinese government has instituted lockdowns to contain this recent outbreak, which affects shipping within China and to and from the country.

All of these delays have a significant impact on waiting times at ports. In Yantian port in Shenzhen, waiting times for vessels to berth have jumped from 0.5 days to 16 days.

How Can Companies Mitigate Their Shipping Costs?

Businesses aren’t at the mercy of ocean shipping companies—they can choose a different mode of transport, add new manufacturing hubs, or even handle delivery themselves where possible.

Use air freight for a faster option

Typically, air freight options are faster but much more expensive than ocean freight options. But since the price of ocean shipping is at an all-time high, air freight may currently be a more viable shipping option for your business. Apparel retailers like Levi Strauss and Tommy Hilfiger are choosing air freight to mitigate their costs.

Read more : Why Is My Printer Skipping Lines

Even though you may not save too much money with this shipping method, your inventory is guaranteed to reach you much sooner, which means you can deliver to your customers faster.

Move your manufacturing locations

China is the global manufacturing powerhouse, but it’s now become the global shipping bottleneck. The ongoing crisis is a lesson that businesses shouldn’t be entirely reliant on one country for their manufacturing needs and should instead move their manufacturing locations to mitigate risk.

Look at outsourcing your manufacturing outside China, preferably closer to your primary markets. One viable manufacturing alternative to China is Vietnam. A 2017 report shows that labor wages in Vietnam for that year were $2.55/hr, while they were $5.21/hr in China.

Go for in-house or self delivery where you can

If you have local manufacturing operations or your customers are close to your site of manufacturing, consider going for in-house or self-delivery of your products.

In-house delivery requires more capital up front to set up your own delivery infrastructure, but it’s cheaper in the long run because you’re not beholden to shipping price fluctuations. It’s not just ocean freight; third-party logistics providers (3PLs) that offer multi-modal logistics like FedEx and UPS are constantly increasing their shipping rates, which affects your bottom line.

You might not be able to completely take over your delivery process right away. On-demand courier services like GoShare help you deliver pallets and less-than-truckloads (LTLs) quickly without having to invest in your own delivery fleet. By working with them, you can refine your internal processes to make a smoother transition to a full in-house delivery model.

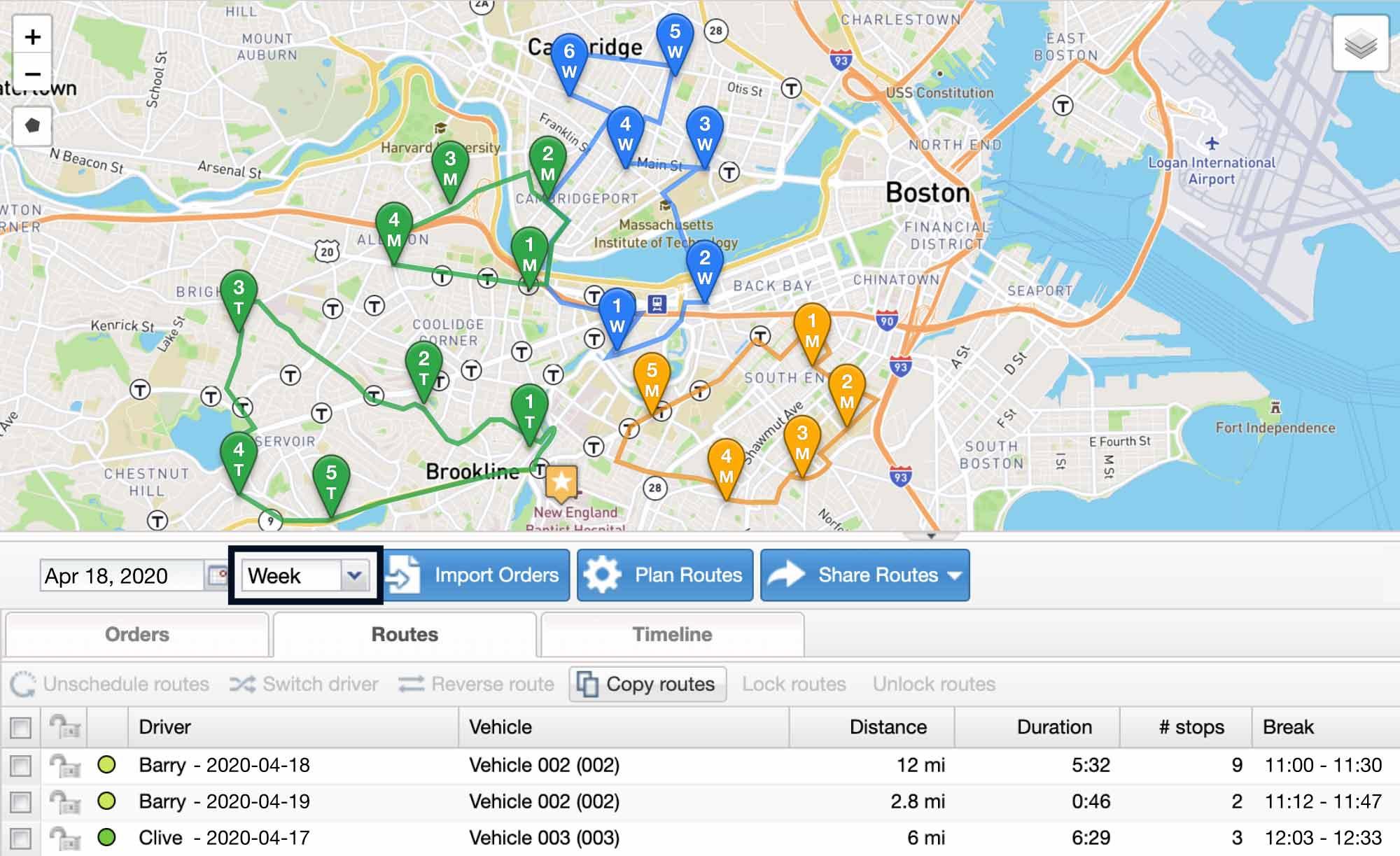

When you go for in-house delivery, you need a system that can help you manage your delivery operations. OptimoRoute does just that:

- Plan and schedule deliveries up to five weeks in advance with OptimoRoute’s Weekly Planning feature. You can plan routes for hundreds of orders in seconds by simply uploading your delivery addresses and your delivery requirements—OptimoRoute’s system takes care of the rest.

- Customize your routes by balancing workloads for each of your drivers. You’ll be able to ensure that each of your drivers has a similar number of orders or hours in the field.

- What if your delivery routes span multiple days? OptimoRoute offers Multi-day Long-haul Routes for these situations.

- Live Tracking gives you visibility into exactly where your driver is throughout their delivery. You can see if a member of your team is delayed or has run into issues in the field.

- On your customer’s end, OptimoRoute offers a number of features that upgrade their delivery experience.

- Delivery time windows align your routes with your customer’s preferred hours of delivery.

- Realtime Customer Notifications inform them where their delivery is via email and text.

- Proof of Delivery gives them confirmation that their delivery has arrived at their location.

Shipping Prices Aren’t Getting Cheaper—It’s Best to Be Prepared

ING estimates that new container capacity won’t bring shipping prices down until 2023. So as a small business, you need to think about the long-term health of your business and act accordingly. It’s important to keep you customers satisfied to maintain a high level of trust.

To improve customer trust in your business, check out this article.

If you choose to go the self-delivery route, OptimoRoute is here to make the transition easy for you. Our logistics management software is easy to use, and it’s free for 30 days to help you get started!

Source: https://t-tees.com

Category: WHY